CASE

Injection moulding production with optical quality inspection

Our customer DEmmould GmbH in southern Germany manufactures injection moulded components for the automotive industry. The customer was looking for an automation solution with additional optical quality inspection for a component that is currently inserted and removed manually from the injection moulding machine. These cylindrical parts are injection-mould around the insert part on one side

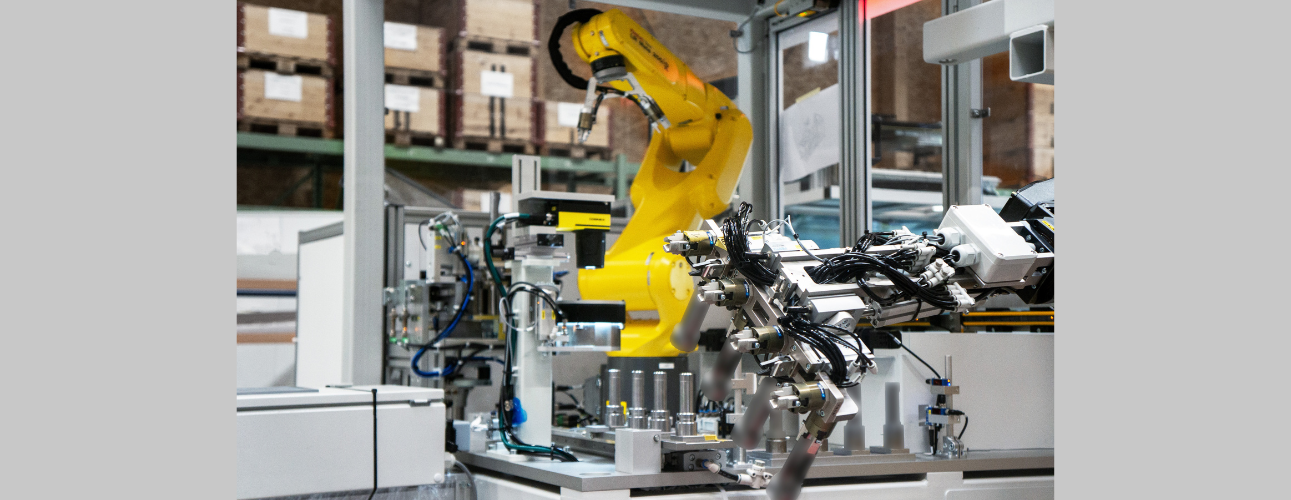

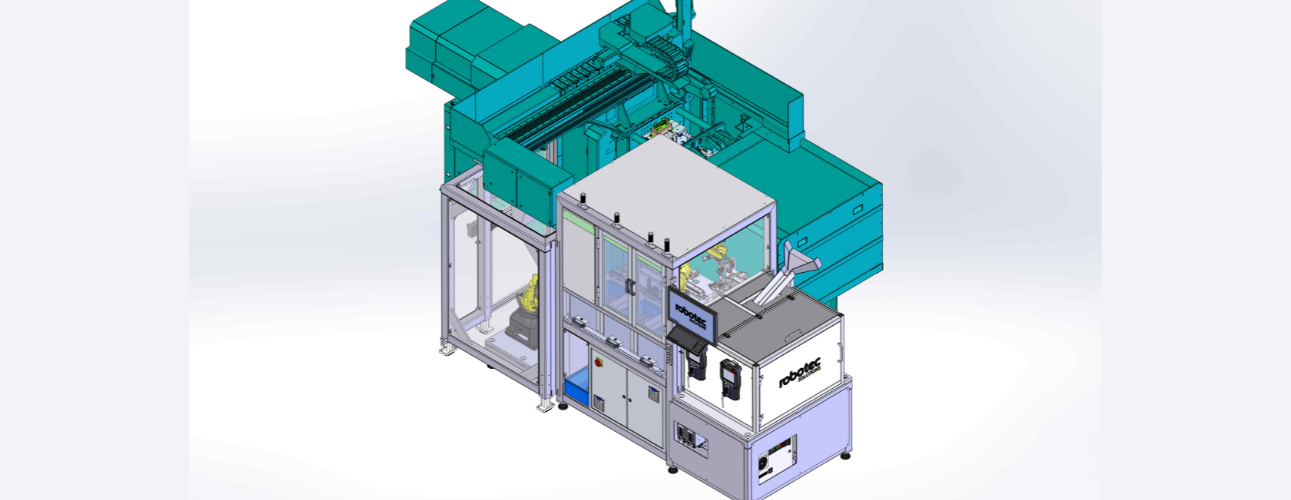

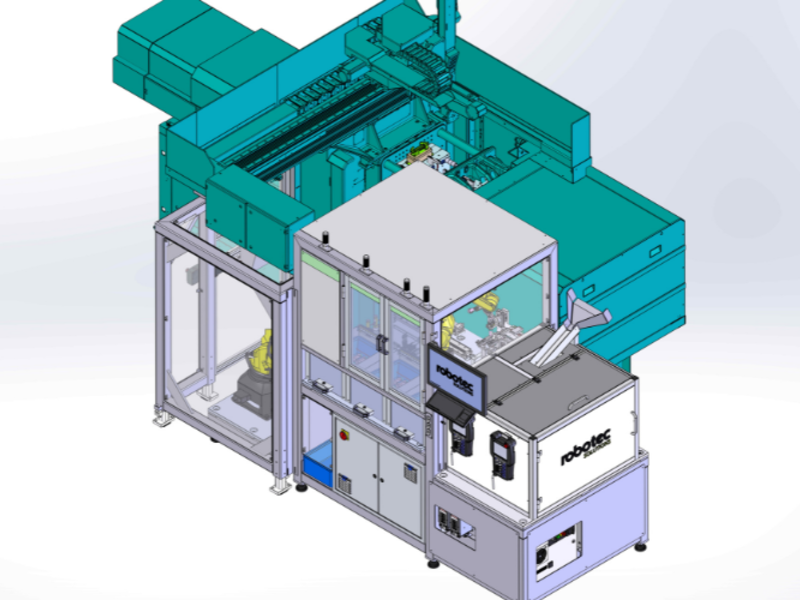

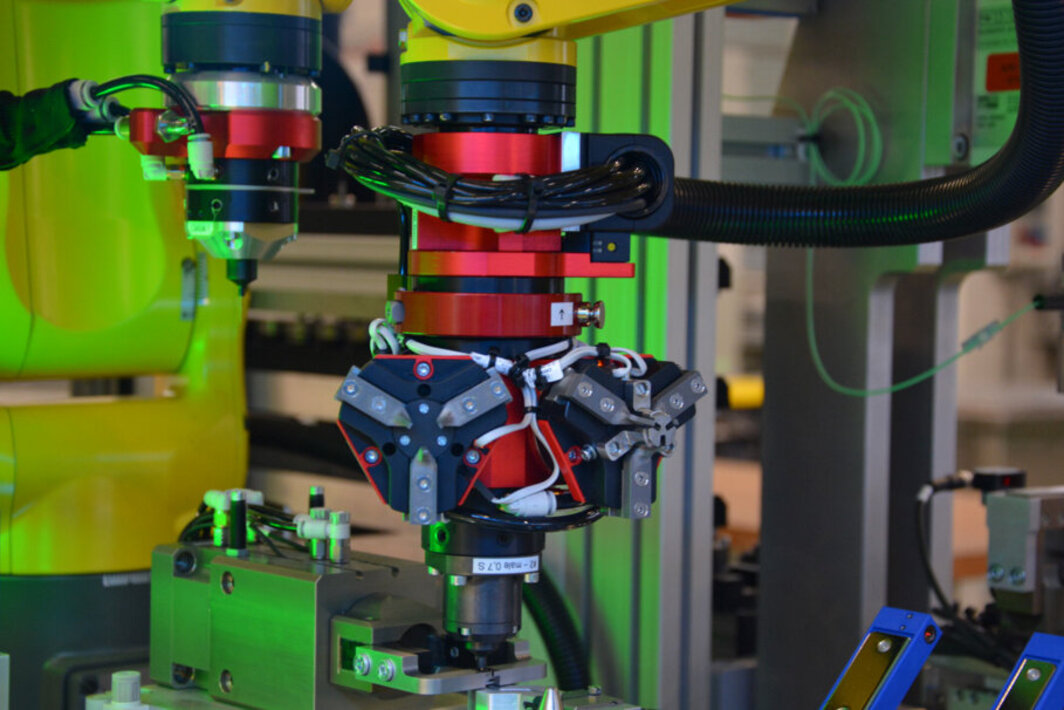

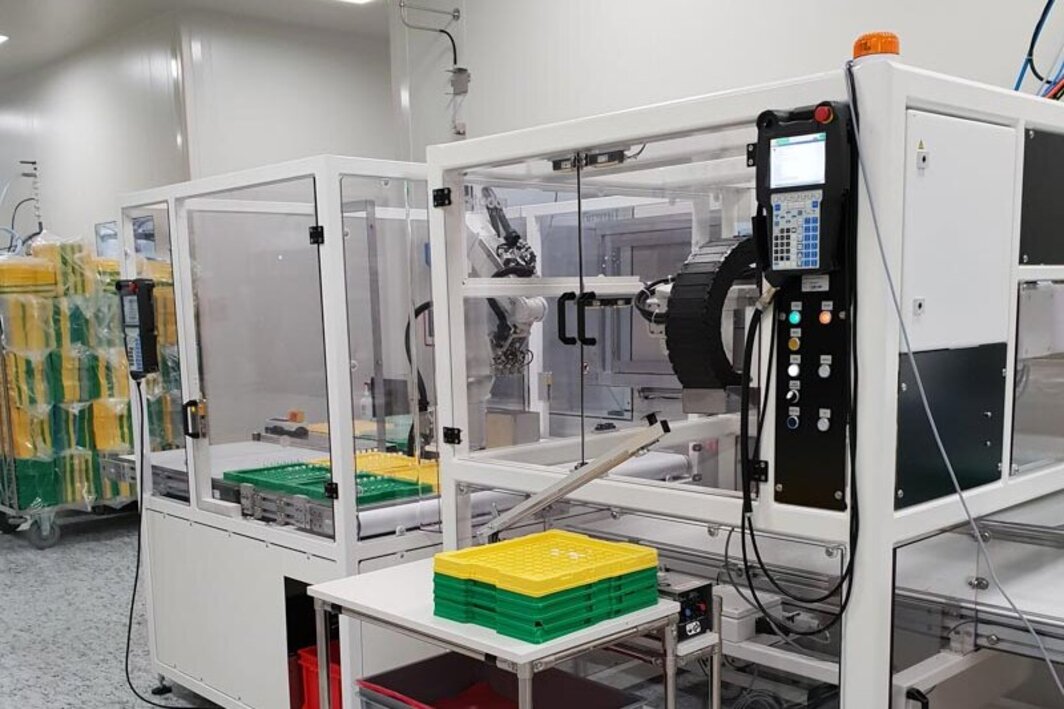

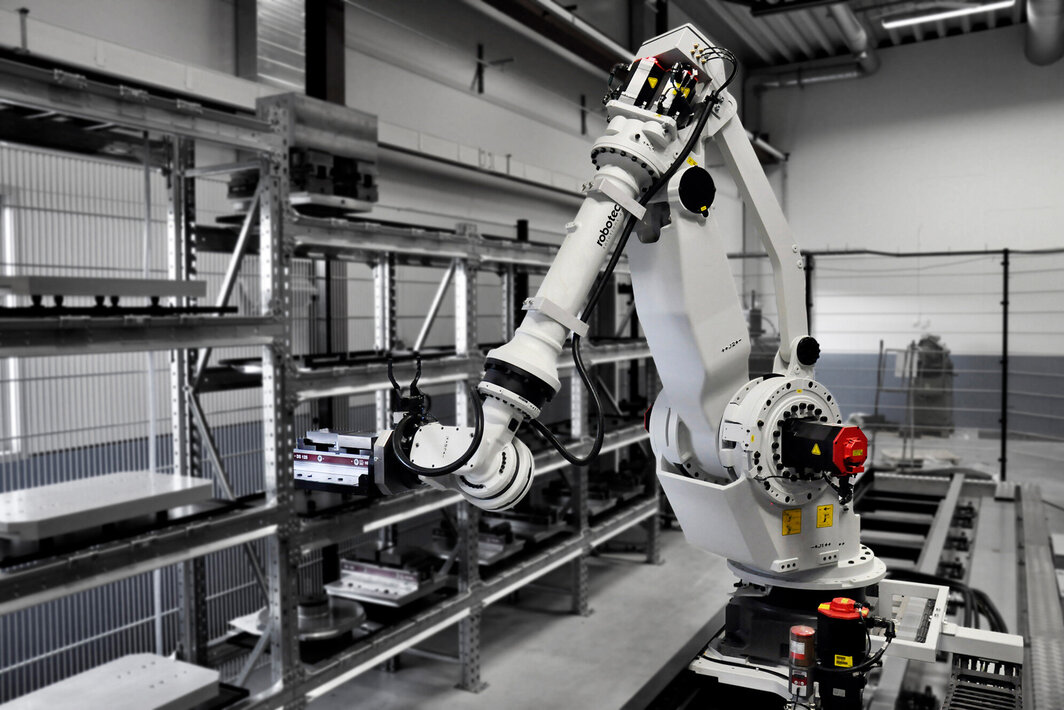

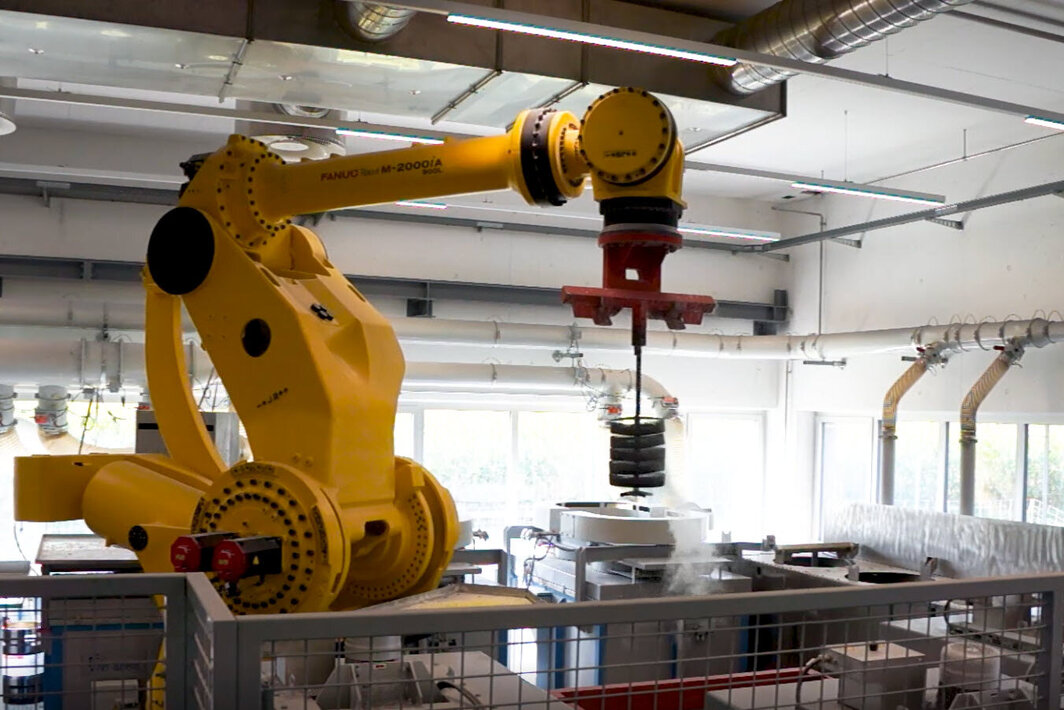

The customized solution from Robotec Solutions includes two robots that handle the parts and a camera that optically inspects the moulded part for quality.

-

Challenge

Metal parts are inserted into a 4-station injection mould tool, where they must be oriented in rotation. A short injection moulding cycle requires a quick removal of the finished parts and the very precise raw parts require an exact insertion into the injection moulding tool.

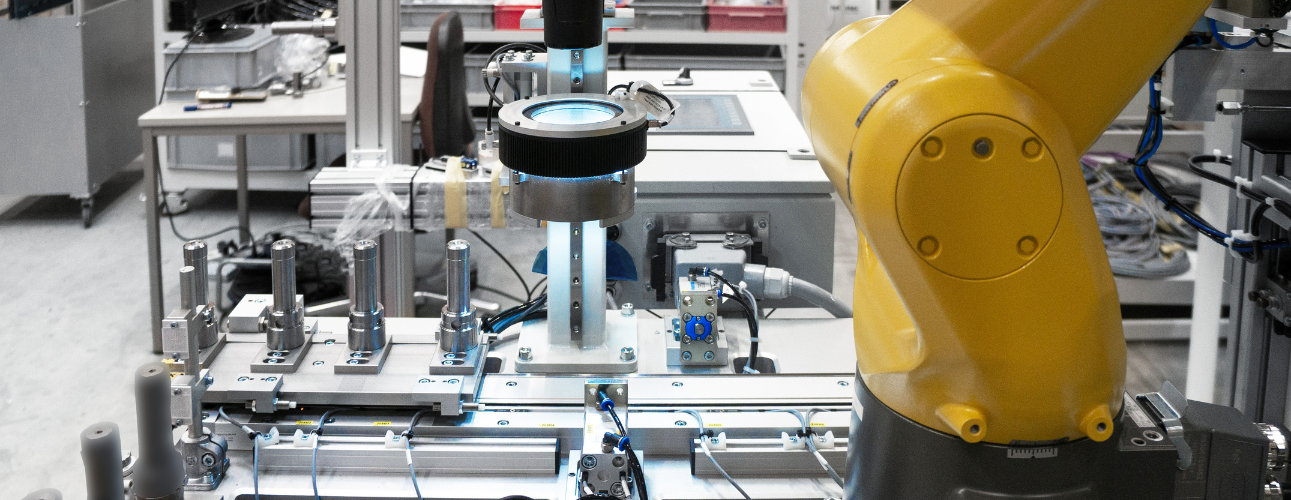

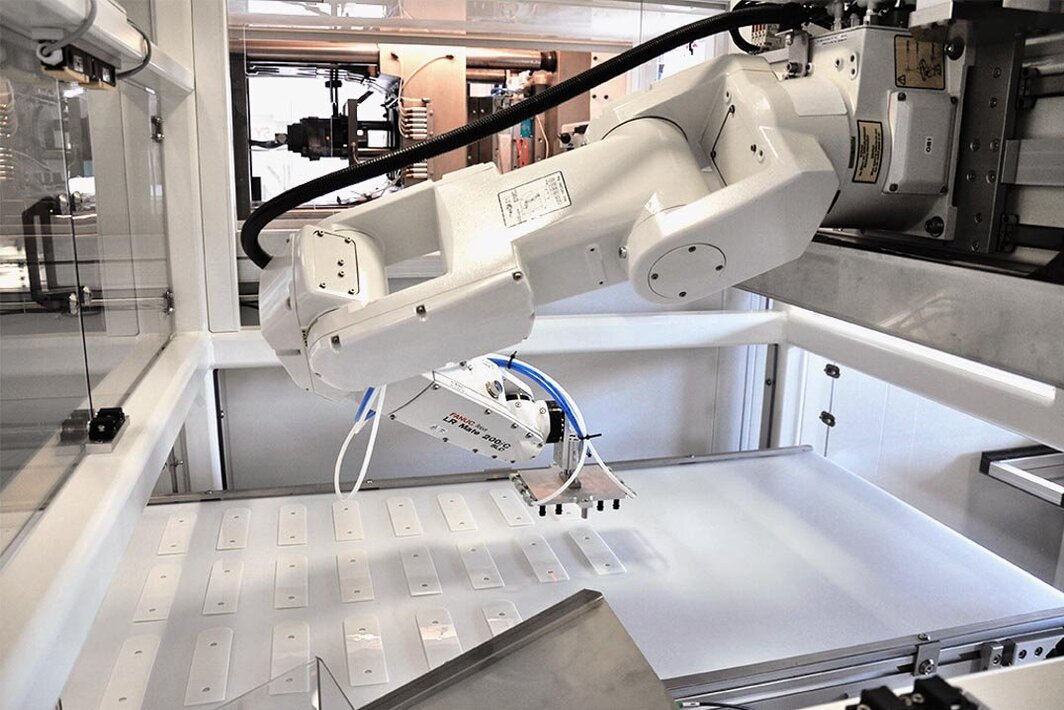

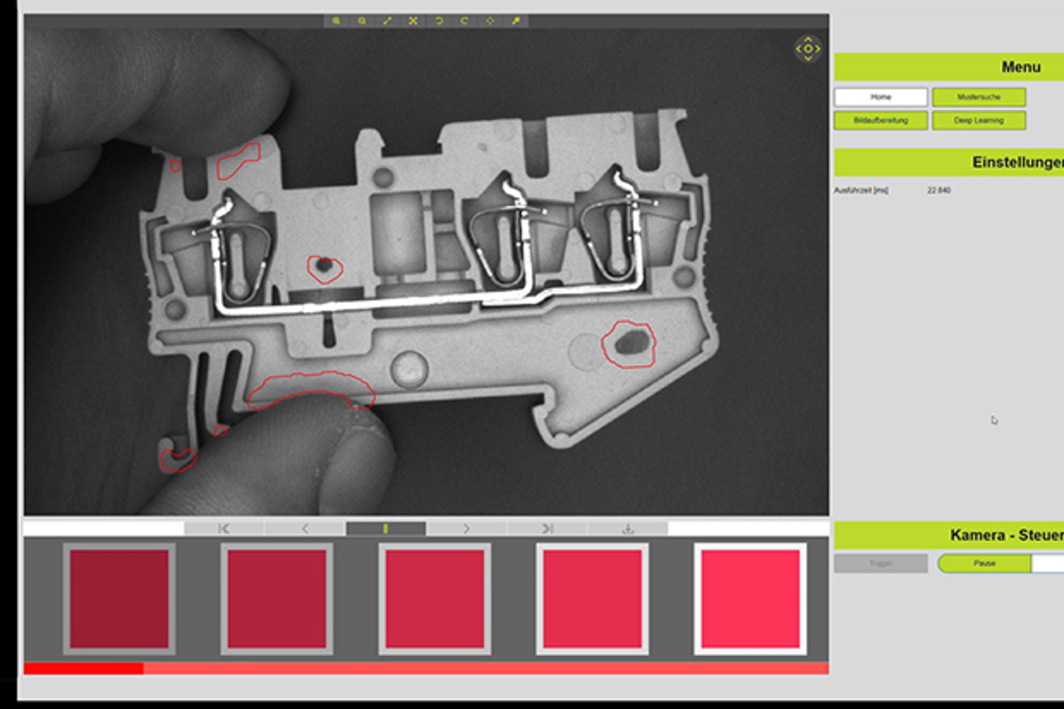

The quality of the surface of the finished parts are visually checked from above.

-

Solution

A robot prepares four raw parts by picking them up from the feeder. These four parts are placed on precision pins - after this they are aligned correctly. The second robot picks up these parts and moves in front of the moulding tool. As soon as this is open, the robot first picks up the finished parts and the sprues, then places the raw parts in the tool.

The sprues are dropped into a box and the finished parts are transferred to a camera station. This now inspects the parts individually. Based on the camera evaluation, the first robot places the parts in boxes or throws them into the bad parts chute.

-

Conclusion

The use of two robots and an optical vision system enables the solution of the required tasks. The high freedom of movement of the robots has resulted in a very compact robot cell. Thanks to the optical system developed by Robotec Solutions itself, only a single photo is required for the optical quality inspection of the finished parts. The evaluation is carried out with the help of an AI software that has been trained based on good/bad samples.

-

Special features

- Cognex vision system with AI

- Precise insertion of blanks into the injection moulding tool

- Interface to the injection moulding machine with handling system

Jörg Lanz, Sales Manager DACH