CASE

Quality control – easy to use but highly efficient

Fischer Connectors, headquartered in Lausanne, develops and manufactures plug connectors for applications that demand maximum precision and reliability. For example, they make plugs with more than 50 gold contacts – and this is just one of thousands of different plugs that they produce.Watch the case live

-

Challenge

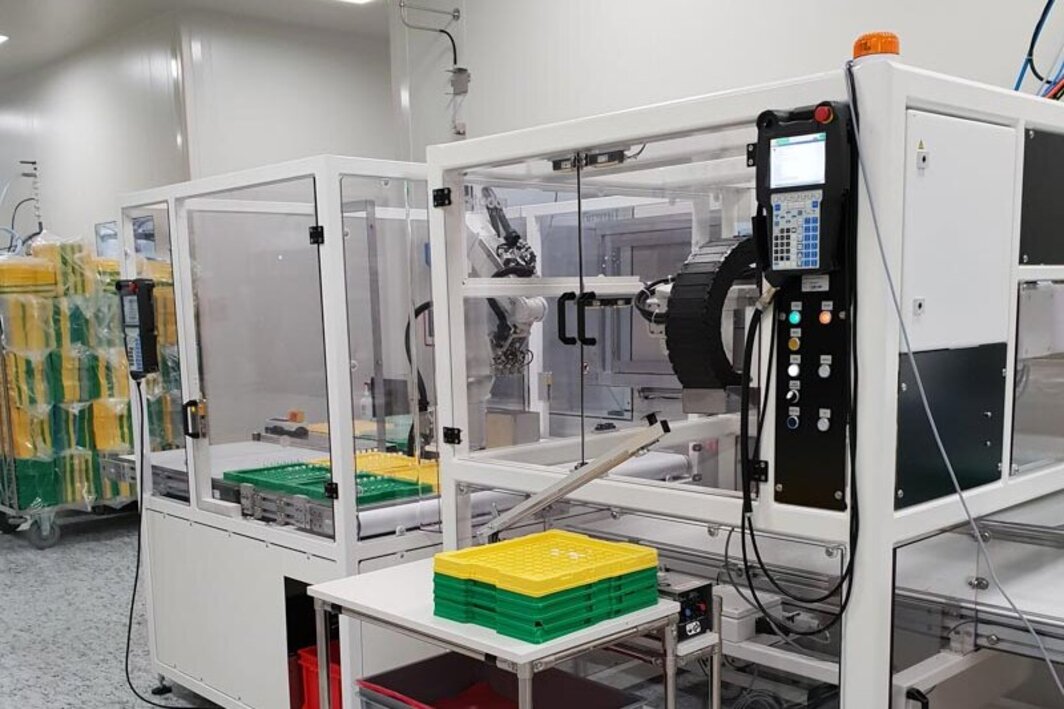

Due to an increase in production capacity coupled with a growing range of different connectors, the company was looking for new assembly machines. The equipment at Fischer needed to be retooled up to five times a day. This required a reliable, quick, and flexible solution.

-

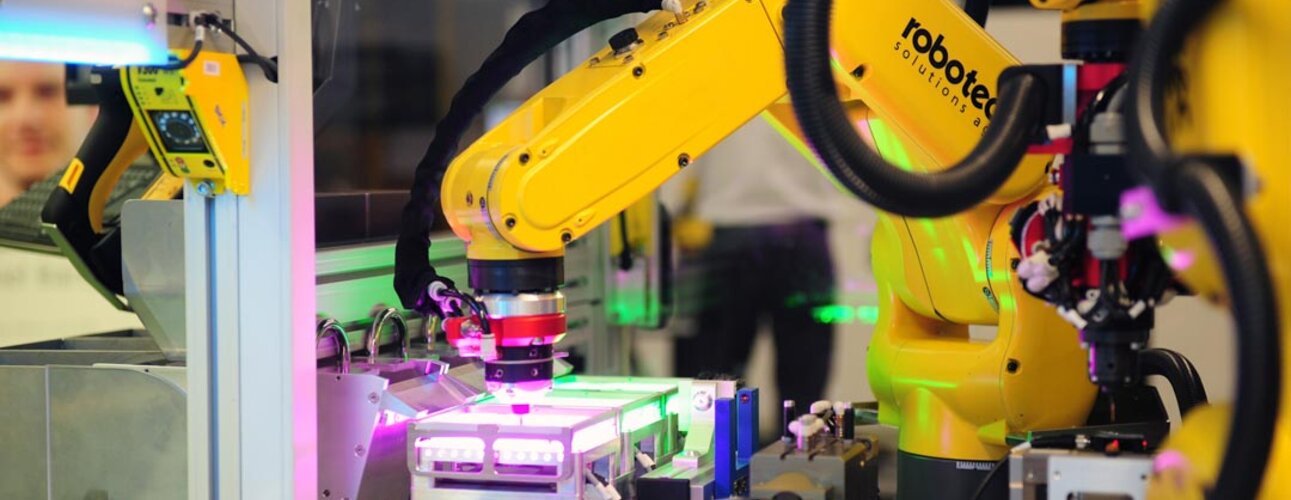

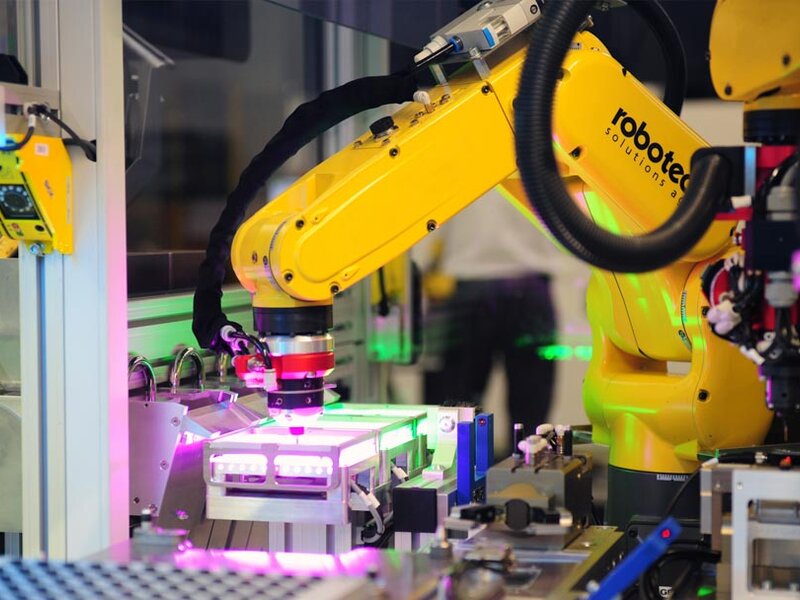

Solution

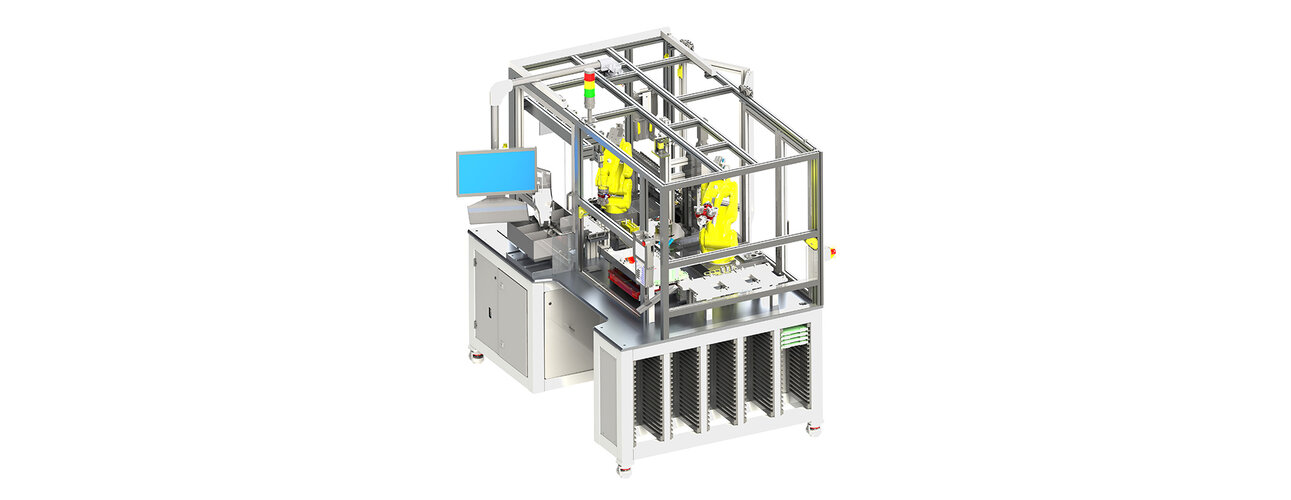

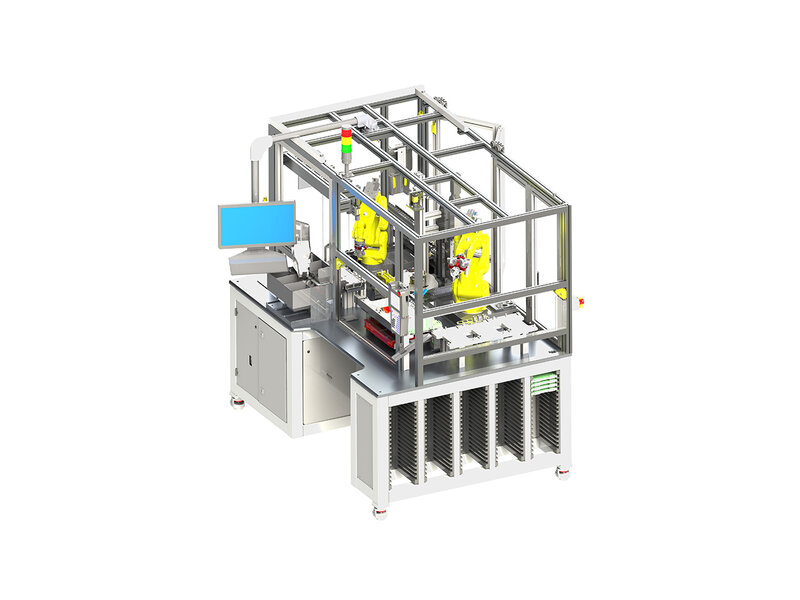

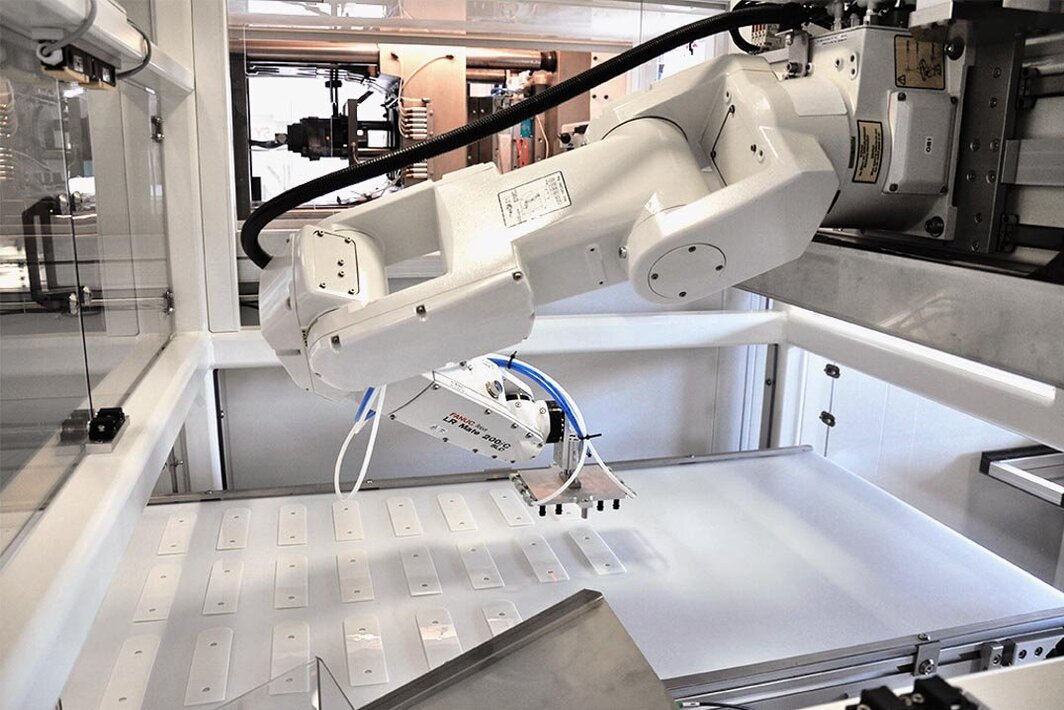

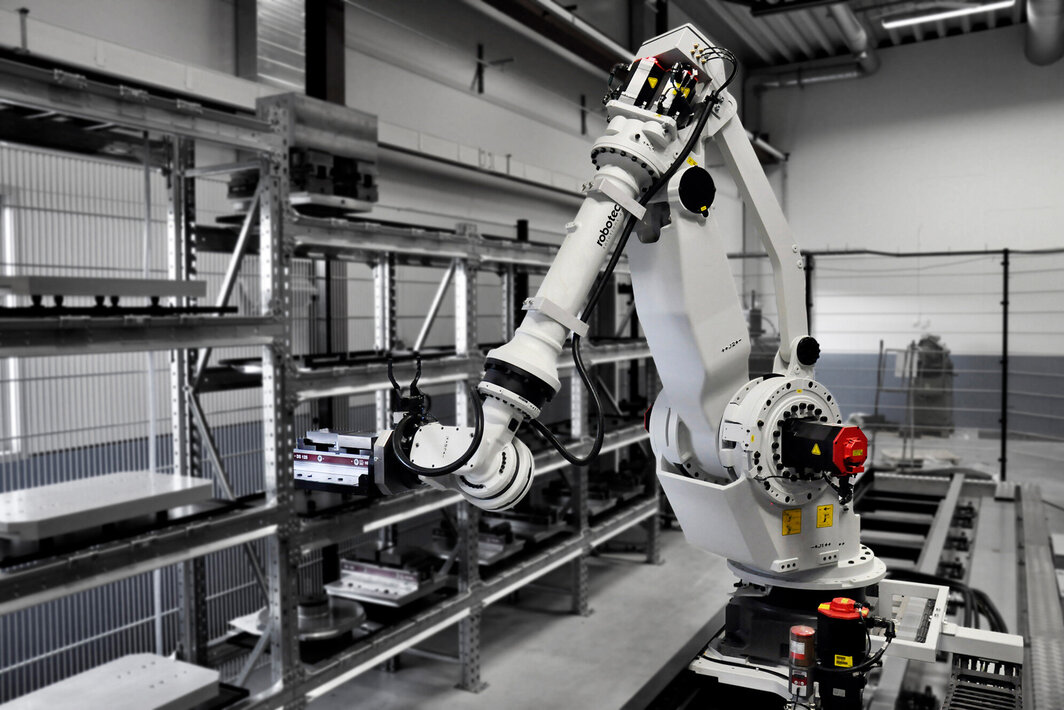

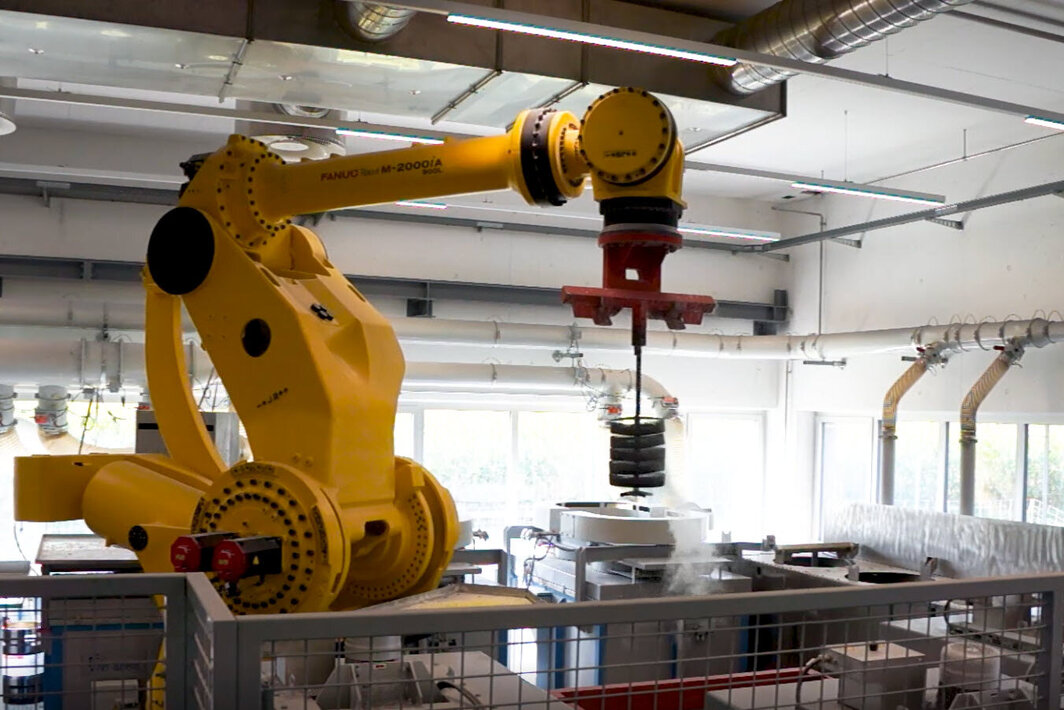

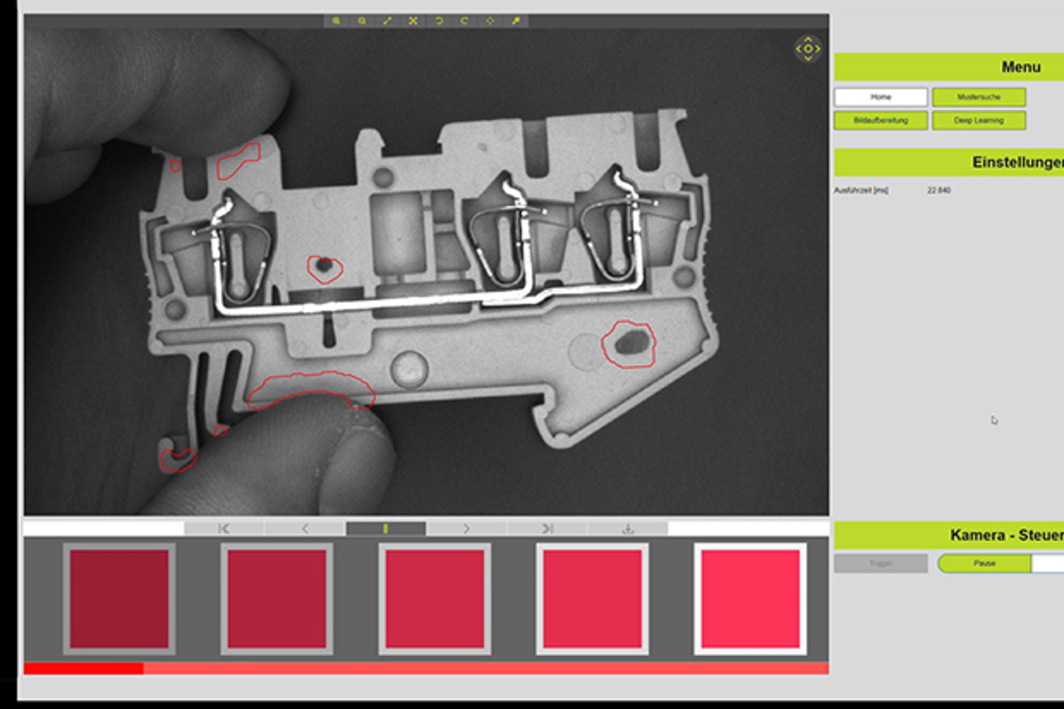

First and foremost, we clarified Fischer’s complex requirements before building a state-of-the-art robot solution: an assembly system with a custom designed feeder, multiple vision systems, servo presses and high-precision axes transforms complexity into simple operation. The system can be retooled in just a few minutes by pushing a button and making a few manual adjustments. The smart human-machine interface (HMI) allows the operator to teach in new plug creations.

-

Conclusion

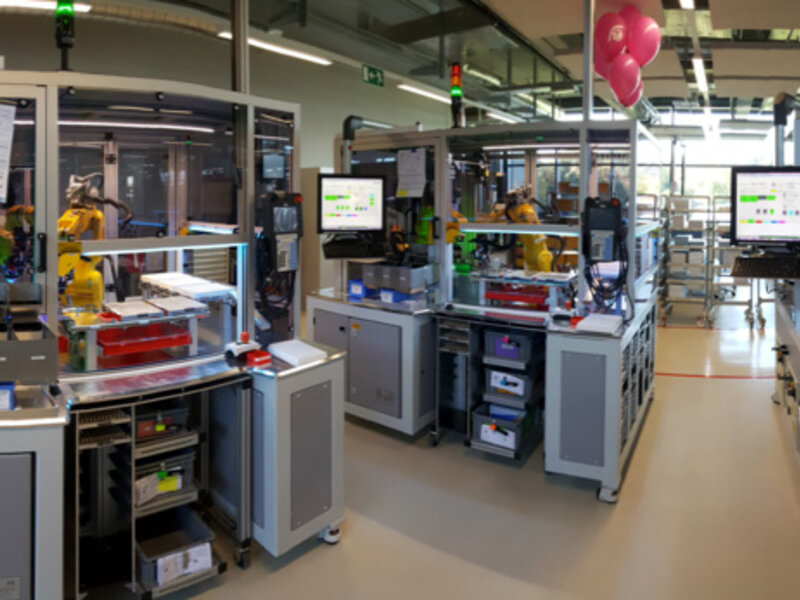

The first system was so successful that the company now has four robot cells in operation 24/7. With more than 700 robots installed in countless applications, this is one of the most complex systems we have ever implemented.

-

Special features

- Wizard-guided HMI

- Easy to retool and expand

- Seven cameras are used to guide movements and choose processes

- Purely electric: 20 servomotors with an encoder for maximum precision

- Changeover time under three minutes

- More than 6,000 different items

Nick Koch, CEO / Sales