CASE

CNC end-to-end Solution – radically reduced setup times

R. Nussbaum AG is a fourth-generation family-owned company that manufactures and sells fittings, installation systems, and services for building services (sanitary and heating). The majority of Nussbaum’s product range is manufactured in-house. Nussbaum is concentrated on select manufacturing processes that are based on highly technical knowledge and allow for competitive product prices. The company places great importance on continuity, innovation, and security. As part of a further development project, they were looking for a state-of-the-art, flexible manufacturing solution for their Trimbach location. Robotec Solutions has partnered with Nussbaum for many years and was awarded the contract for this project.

-

Task

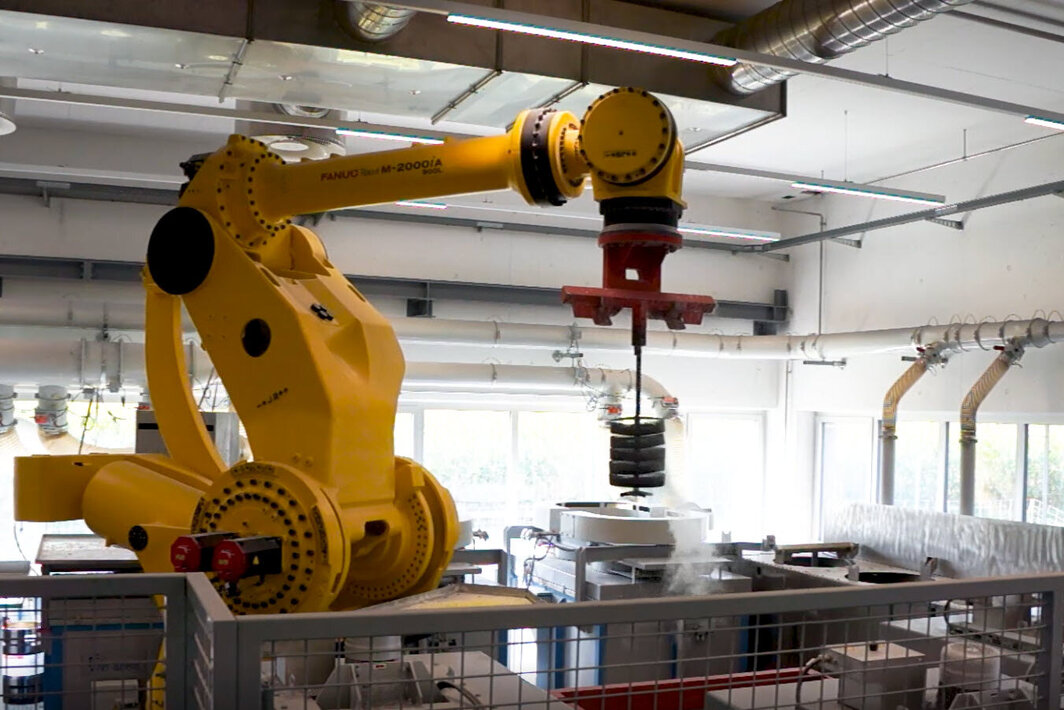

Countless water distributors and drains are manufactured on milling and turning machines. New shapes, new alloys, and the pressure to reduce setup times to just 15 minutes demanded an innovative manufacturing concept.

-

Solution

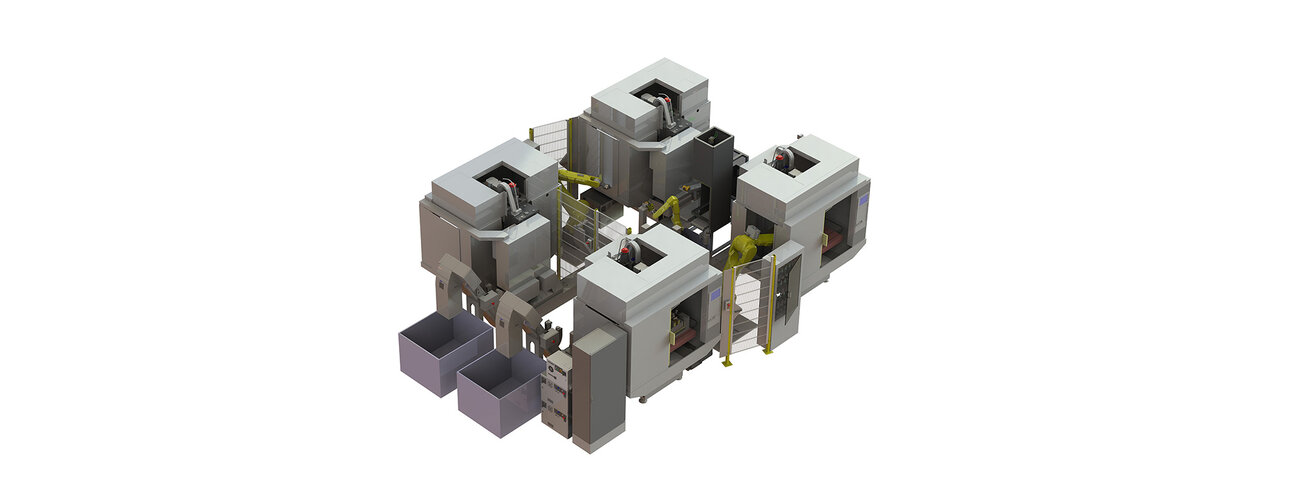

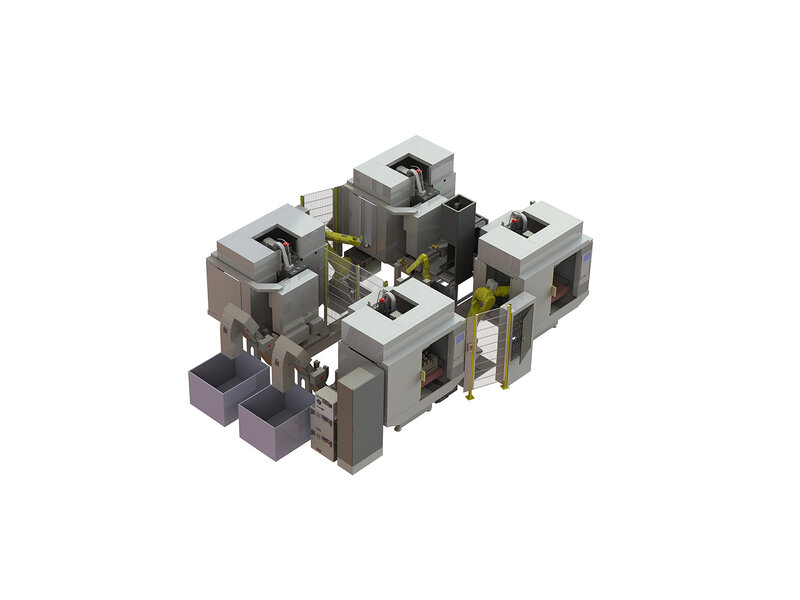

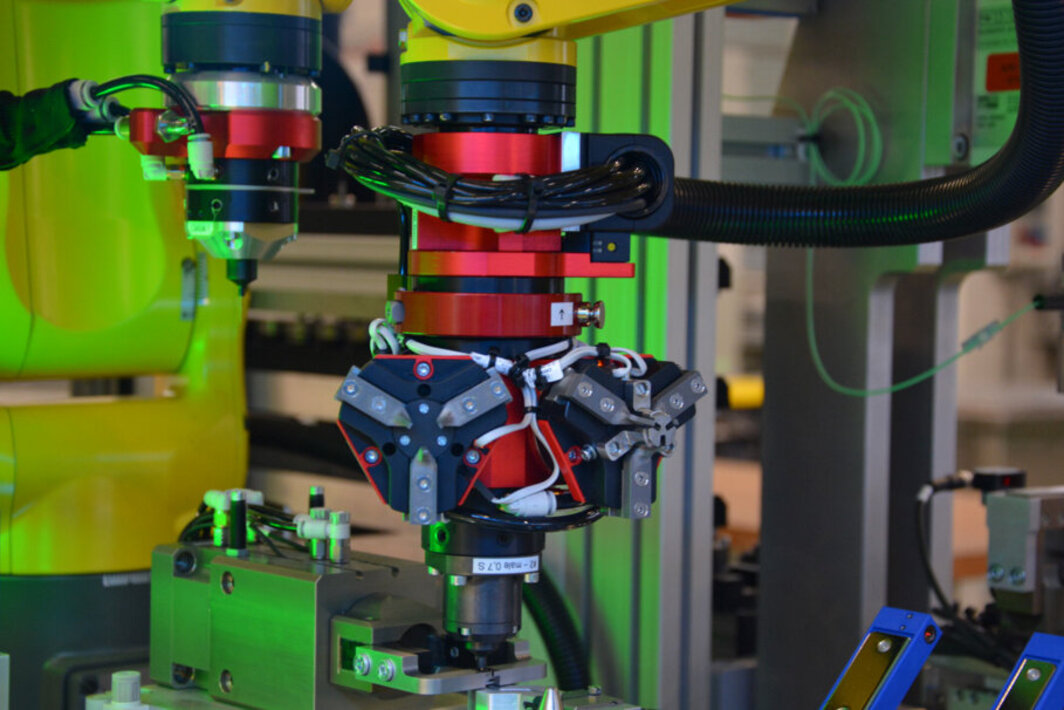

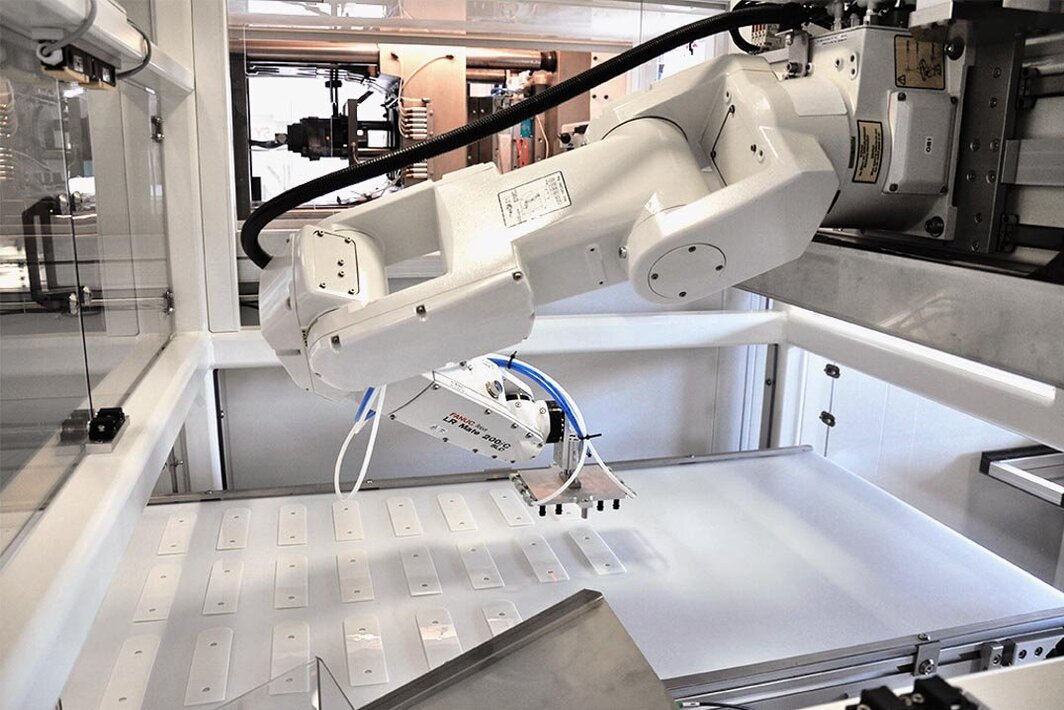

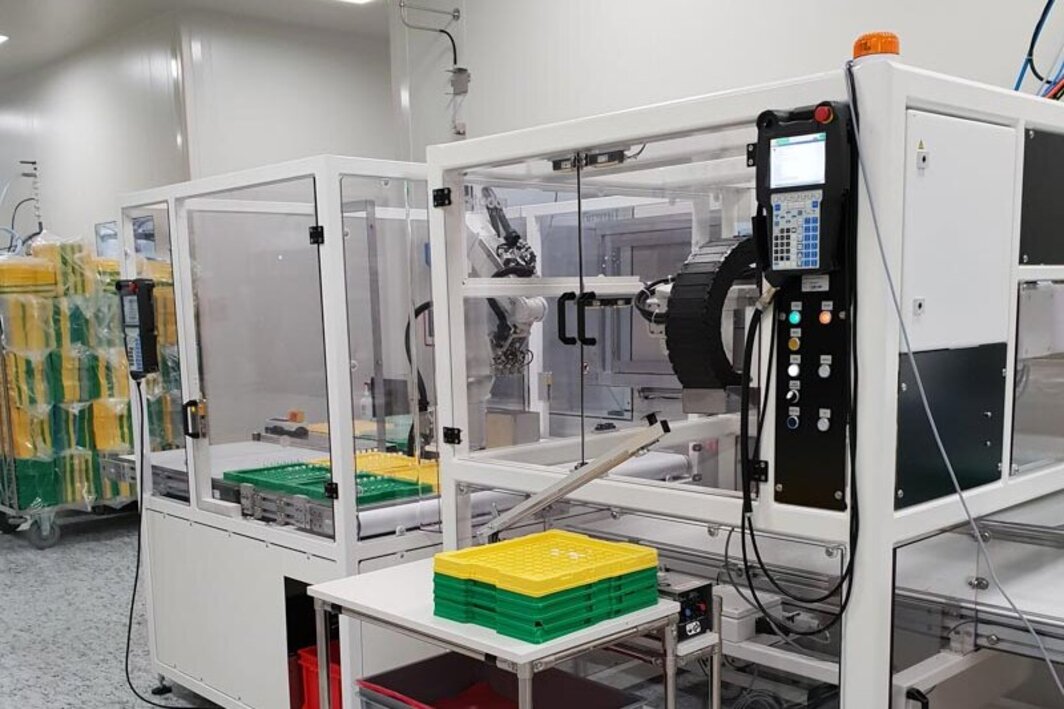

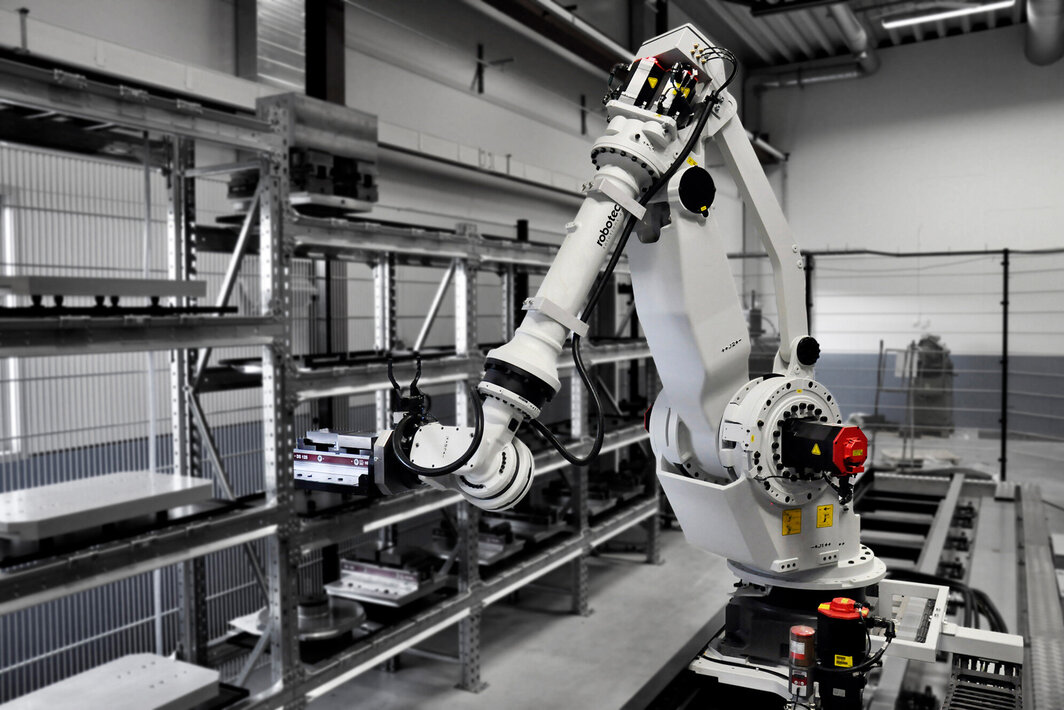

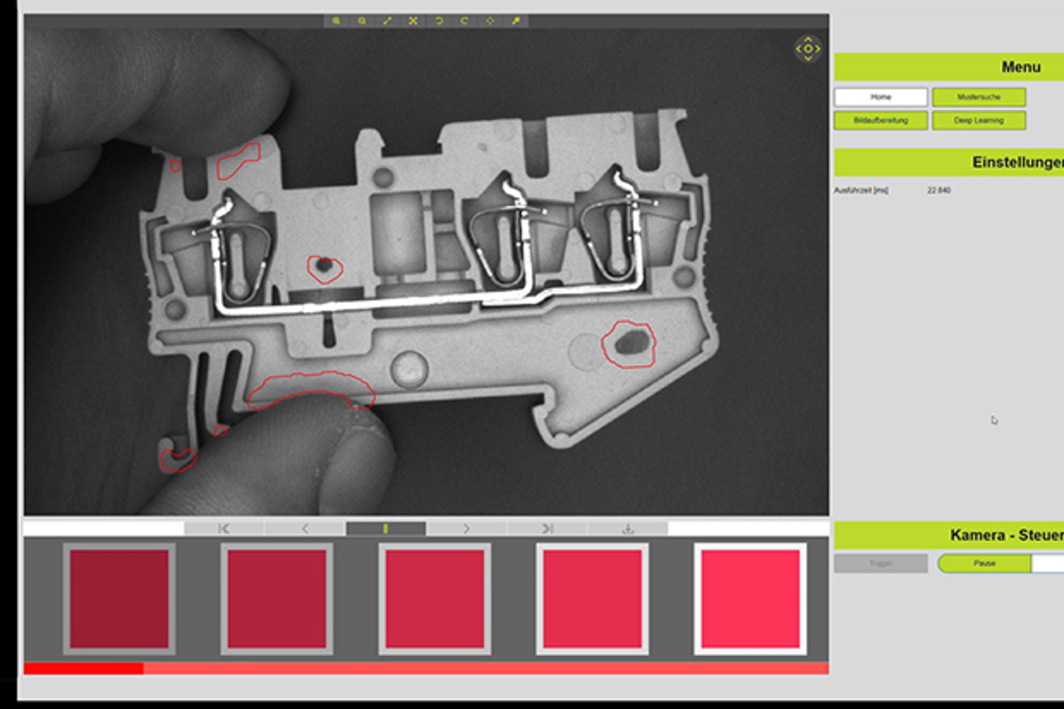

Robotec Solutions’ vast experience and close relationship with Fanuc resulted in a brand-new custom application. It combines the guidance of machine vision, milling machines with electric clamping devices, and robots with sensitive gripping technology, as well as a control architecture that was developed in-house – all from a single source.

Robotec’s parent company, with a branch office in Stuttgart and close ties to Fanuc, was able to call upon Fanuc Europe’s milling and drive lab. Together, they broke new ground, taking an unorthodox approach that was then thoroughly tested and refined.

The advantages of the system: quick conversion times and ease of use. Fanuc RoboDrill milling machines were expanded with custom-built quick loading doors and servo-driven clamping devices. Robots with vision technology and Industry 4.0 interfaces connect the sub-applications. This allows settings and process steps to be adjusted automatically to production in a matter of seconds.

-

Conclusion

The highlight of the system is the fast, purely electric clamping device. It makes it possible to shave off a large number of seconds when switching parts while also achieving an extremely high cycle rate for the system as a whole. The vision technology, automatic switching of the milling tools by robots, and the menu-guided master controller allow for extremely short conversion times. Nussbaum is now optimally equipped for the growing demands of a dynamic market.

-

Special features

- Conversion in less than 15 minutes (for four milling machines, incl. automation)

- Networked production with central control via HMI

- Milling machine with electric clamping device

- Milling machine with robot-based tool change

- Training for manufacturing employees so they can teach in new reference parts

Jörg Lanz, Sales