CASE

Pipette tip production

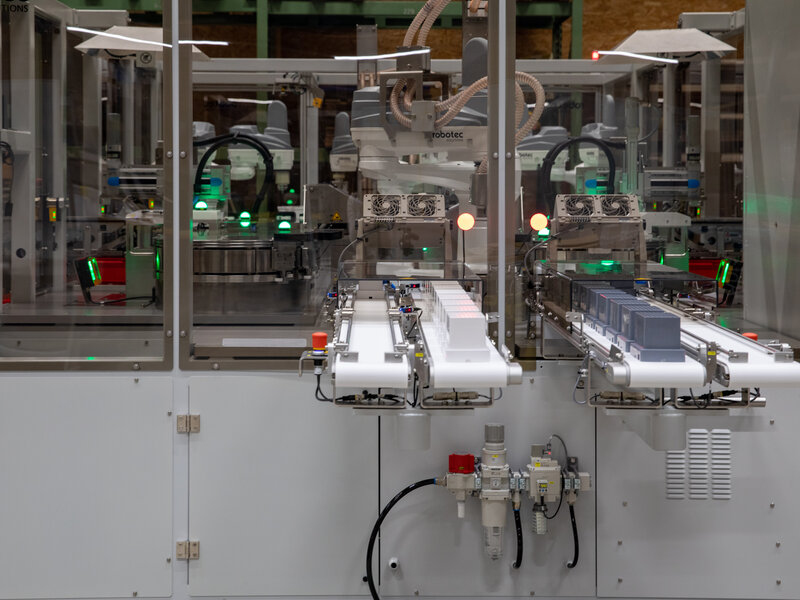

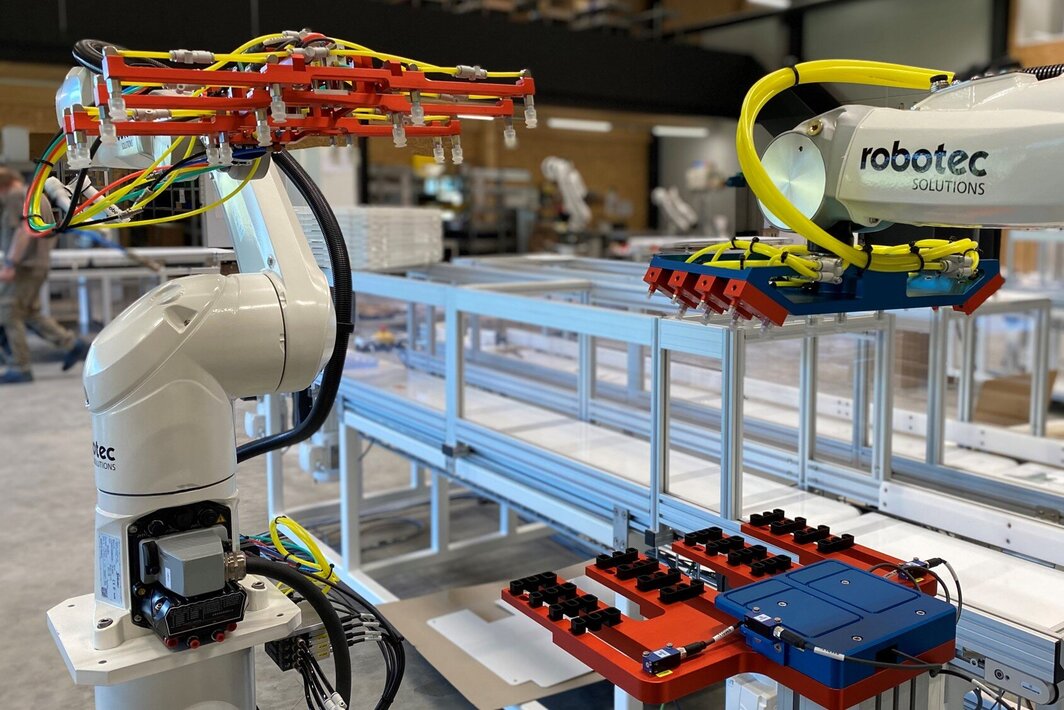

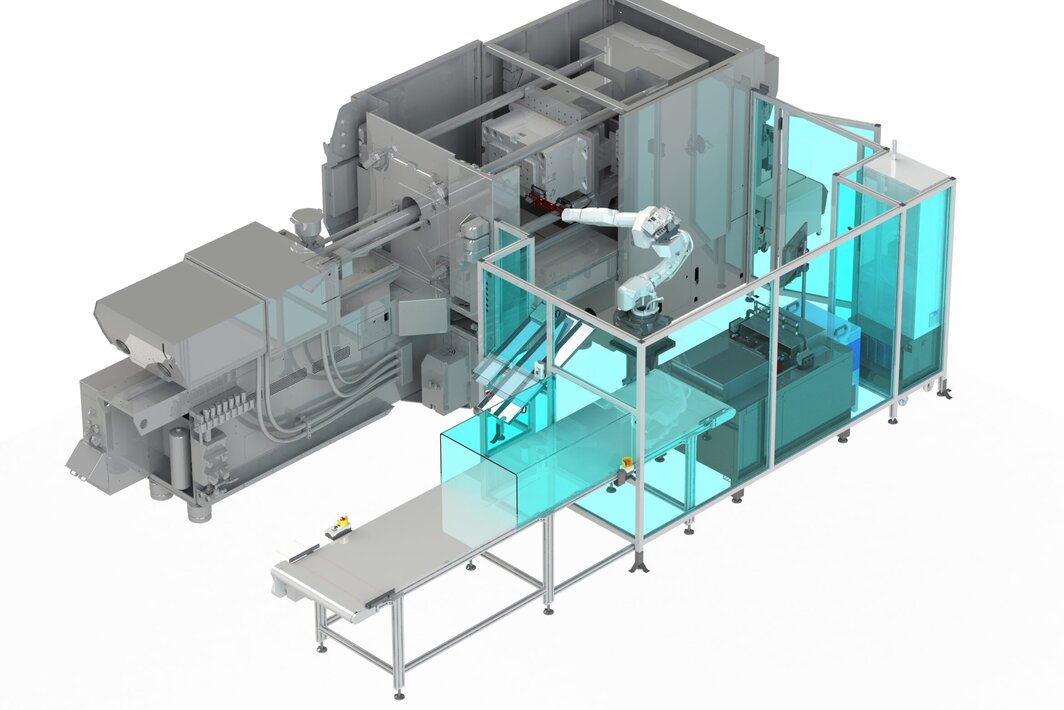

Manufacturing of pipette tips requires the highest level of production. Robotec Solutions convinces with a unique automation concept, that can hardly be surpassed in its compactness, performance and technology level. The use of seven Stäubli Scara robots, three Acopostrack transport loops, state-of-the-art machine vision and laser scanning systems has resulted in one of the most modern and compact production solution in the history of Robotec. The system is operated in a GMP C clean room environment, has low maintenance level and is almost emission free.

Challenge

Within a few seconds, 96 pipette tips are to be transferred, assembled, inspected and finally packed into a sales rack. In addition to the very tight measurement tolerances for the pipette tips, the entire traceability is also a major challenge. In addition, the system had to be designed as “easy to use” and should requires minimal maintenance: All with the goal of obtaining the highest possible overall equipment effectiveness OEE.

Solution

At the customer's request, the system was configured for loading and unloading by operators – at a later stage this could fully automated – direct from an injection molding machine to the finished and packed box.

- There are two different types of pipette tips that are processed simultaneously by the system and finally packed together in a rack.

- The pipette tips are gripped from a rack by a suction pad and transferred to the magnetic shuttle loop.

- The shuttles receive the information on which place which cavity is located and then drive through at the following stations:

- Visual bottom view control

- Filter Pressing station

- Top-View checking of filter position

- Removal of bad parts

- Refilling of good parts

- Transfer to the sales rack

The sales rack is labeled, checked for completeness, and then moved out of the cell via a conveyor belt - a packaging line could also be added directly here.

The central, graphical user interface via a big touchscreen enables the operator to use the system intuitively. Appropriate user guidelines and simple operation are intended to prevent errors on the part of the operators and to ensure the highest possible machine availability.

The system was validated and qualified according to the Robotec GMP standard and met the highest quality standards.

Conclusion

Within a very short time, the Robotec team has built one of the most advanced automation solutions for controlling, filtering and packaging pipette tips. The modular design, the use of state-of-the-art technologies and the simple operation characterize the system. In addition, the cell has low maintenance level and is almost emission free.

Key attributes

- Well thought-out "bring-in" in concept: The system is divided into 4 parts to make it as easy as possible to bring it into the clean room

- Use of the latest technologies such as Stäubli Scara robots or the Acopostrack transport system based on magnetic technology

- Compact design, easy to clean and low maintenance

- Intuitive user interface prevents unintentional downtimes

- Traceability of the entire production on the plant as well as an OPC UA interface for data transfer to the customer system

Jörg Lanz, Sales