CASE

«Cobot» in action

Men and Machine – collaborative robots support workers

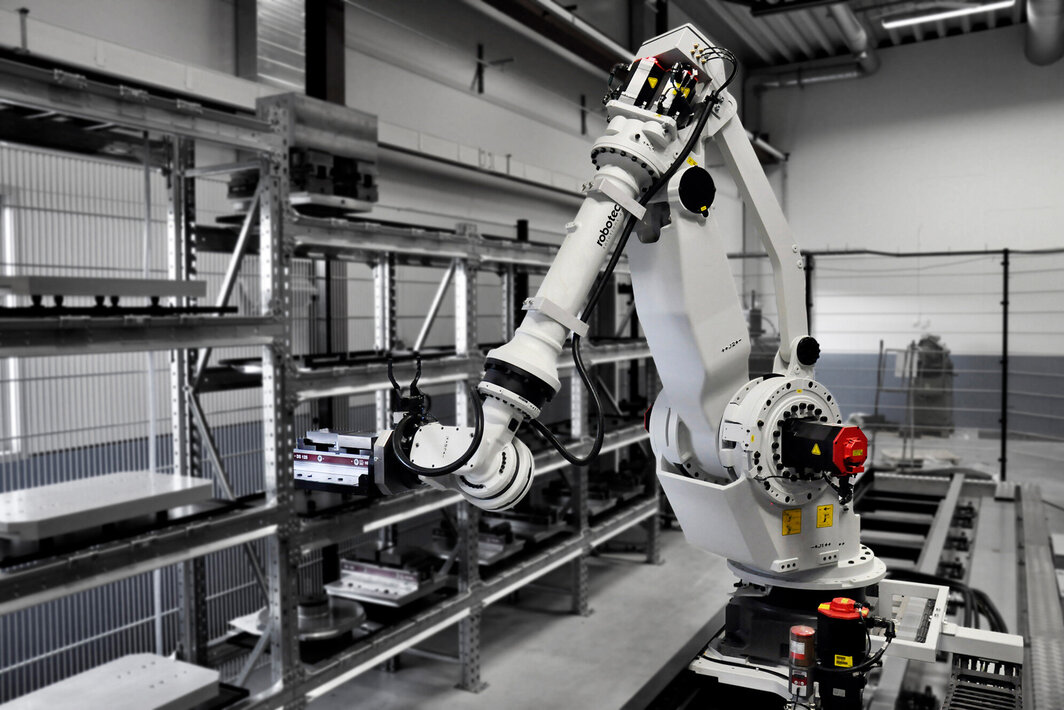

A collaborative robot, usually called a «cobot,» handles repetitive work processes precisely, safely - and without a safety fence together with workers. In addition, they are easy to program, are user-friendly and intuitive to operate. Employees can be relieved of one-sided, physically exhausting tasks and instead be deployed for complex work.

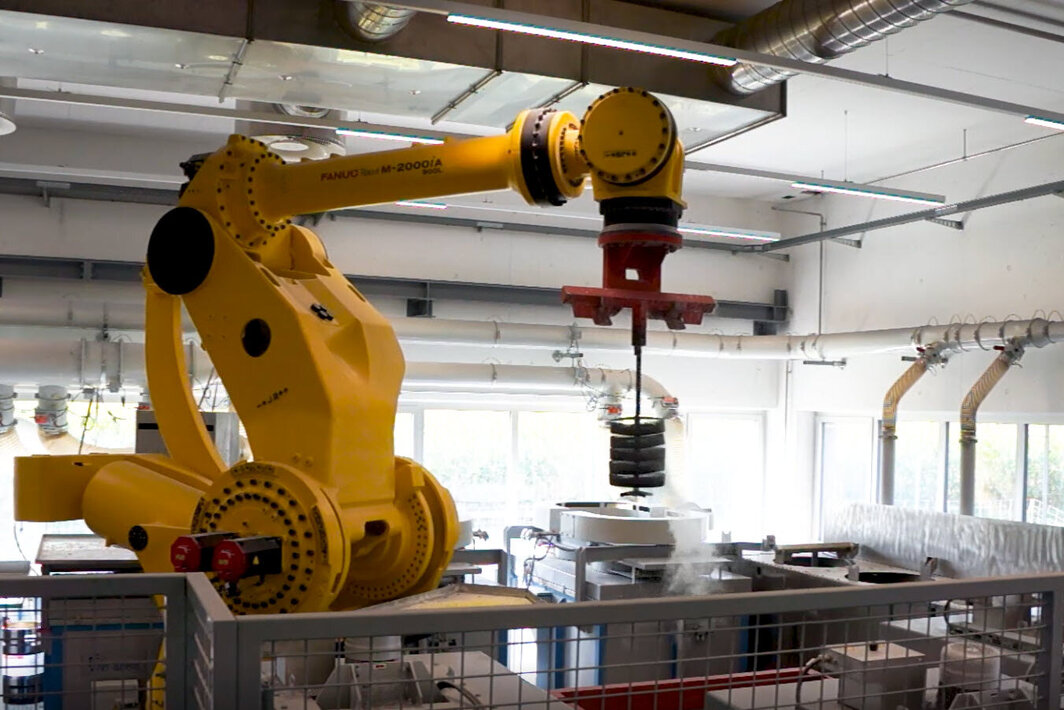

A well-known plastics production company relies on the Fanuc Cobot CRX-10 in its laboratory. A functional automation solution from Robotec Solutions does its job reliably in 3-shift operation after a very short planning, setup and implementation time.

-

Challenge

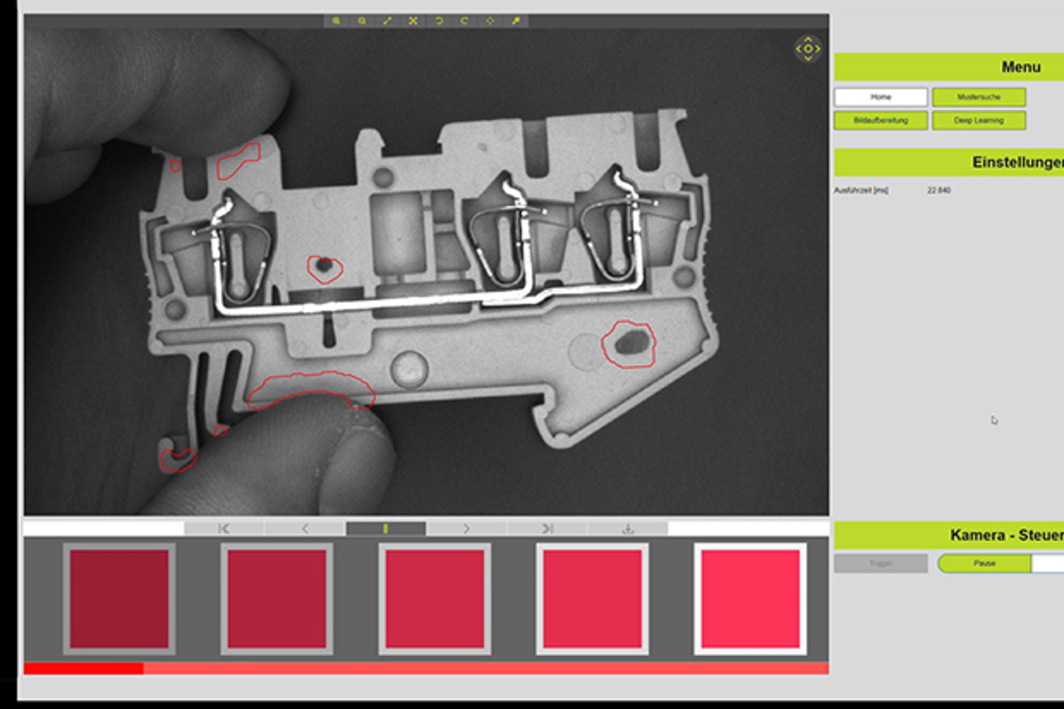

Small individual parts are repacked by hand in large numbers, which is demanding and time-consuming and also involves great potential for errors and damage. Automation had to be implemented in the shortest possible time to relieve the employee and free him up for more demanding tasks. The specification of a realization within two months was not feasible with conventional methods. For this reason, the solution with a cobot was chosen, which was already available in the demo room at Robotec Solutions.

-

Solution

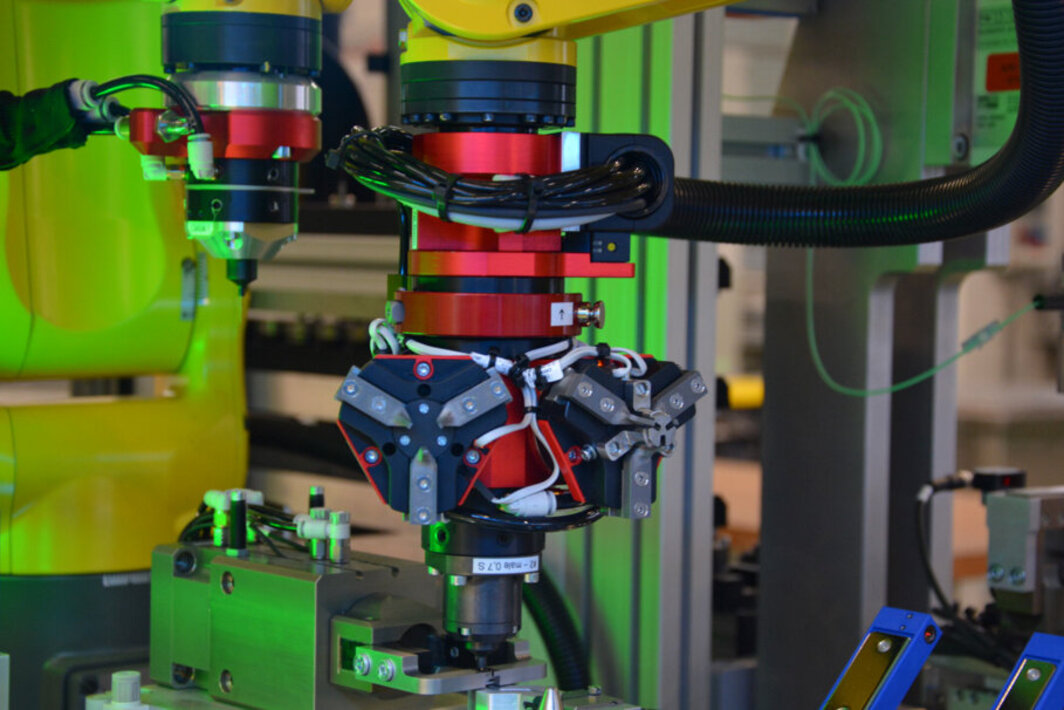

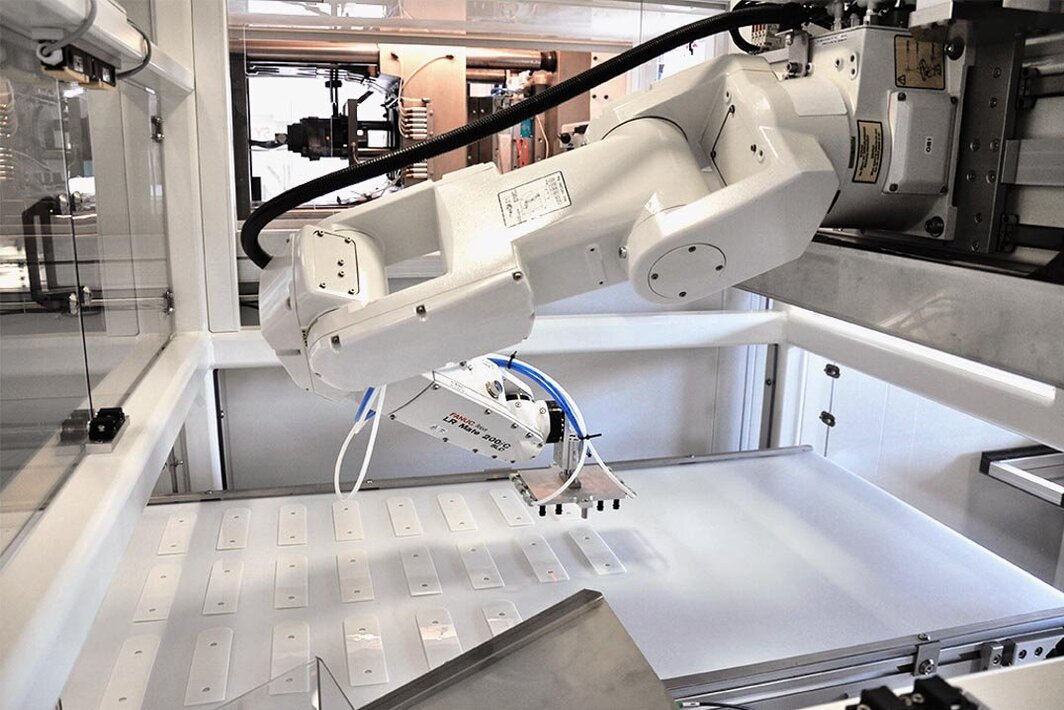

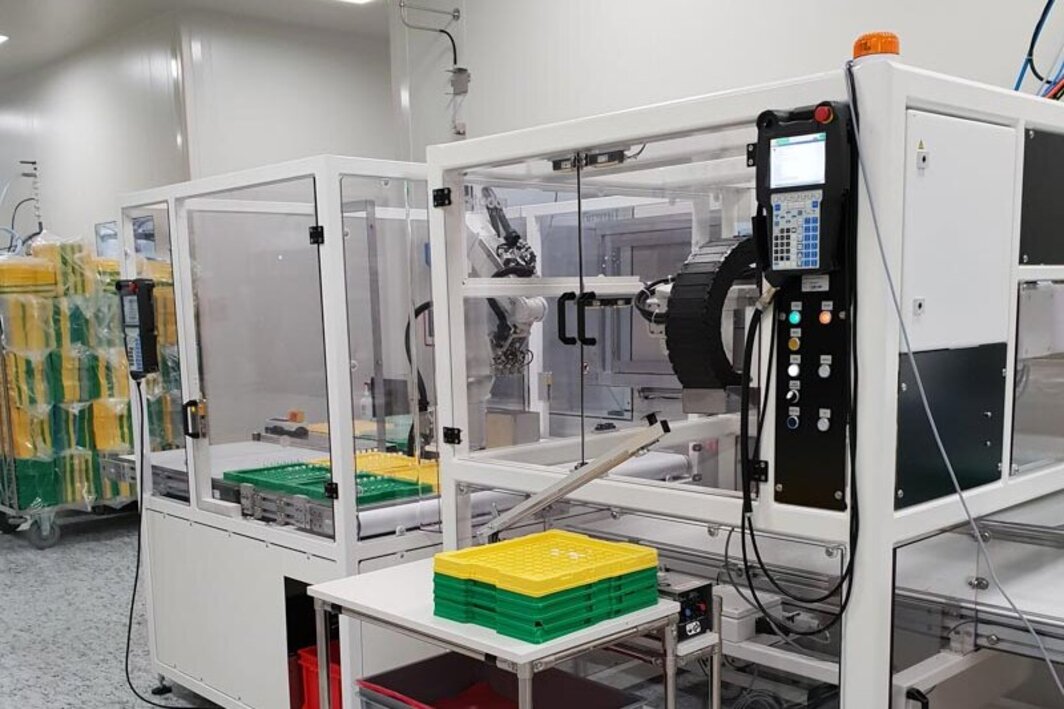

The solution is simple: A Fanuc Cobot CRX 10iA on a stable steel structure, equipped with an electric gripper and a assembly plate for the input and output of parts. Operation is commanded via the robot's touch panel, self-explanatory.

The entire planning, implementation including wiring and programming was done by the trainee department.

After 10 weeks the system was in service, the training and the introduction in shift operation was implemented. Feedback from the customer: «A complete success, the solution has convinced. Further ideas are already being planned... ».

-

Conclusion

Cobots are suitable for simple tasks in many application areas. Robotics know-how or programming skills are only necessary to a limited extent for this form of automation.

Operation is possible after just a few hours, simple programming after half a day to a day. Everything works intuitively and follows a clear system.

Classic applications can be found in the field of CNC, pick and place, quality inspection or product packaging.

-

Special features

○ Collaborative

○ Secure

○ Easily programmable

○ Intuitive

○ Quick to use

○ Highly flexible

Nick Koch, CEO / Sales

![[Translate to English:] Teach Pad des Cobot der Robotec Solutions.](/fileadmin/_processed_/4/2/csm_Cobot_Teach_Pad_Robotec_Solutions-2_1fcce81b6b.jpg)

![[Translate to English:] Arbeitsplatz mit dem Cobot Roboter der Robotec Solutions](/fileadmin/_processed_/8/d/csm_Cobot_Roboter_von_Robotec_Solutions_mit_Mitarbeiter_502e2c1683.jpg)

![[Translate to English:] Arbeitsplatz mit dem Cobot Roboter von der Robotec Solutions](/fileadmin/_processed_/4/4/csm_Cobot_Roboter_an_Arbeitplatz_von_Robotec_Solutions__b3b77c4cf1.jpg)

![[Translate to English:] Teach Pad des Cobot der Robotec Solutions.](/fileadmin/_processed_/4/2/csm_Cobot_Teach_Pad_Robotec_Solutions-2_46abc67093.jpg)

![[Translate to English:] Arbeitsplatz mit dem Cobot Roboter der Robotec Solutions](/fileadmin/_processed_/8/d/csm_Cobot_Roboter_von_Robotec_Solutions_mit_Mitarbeiter_57abb807b3.jpg)

![[Translate to English:] Arbeitsplatz mit dem Cobot Roboter von der Robotec Solutions](/fileadmin/_processed_/4/4/csm_Cobot_Roboter_an_Arbeitplatz_von_Robotec_Solutions__867fa7ca10.jpg)