CASE

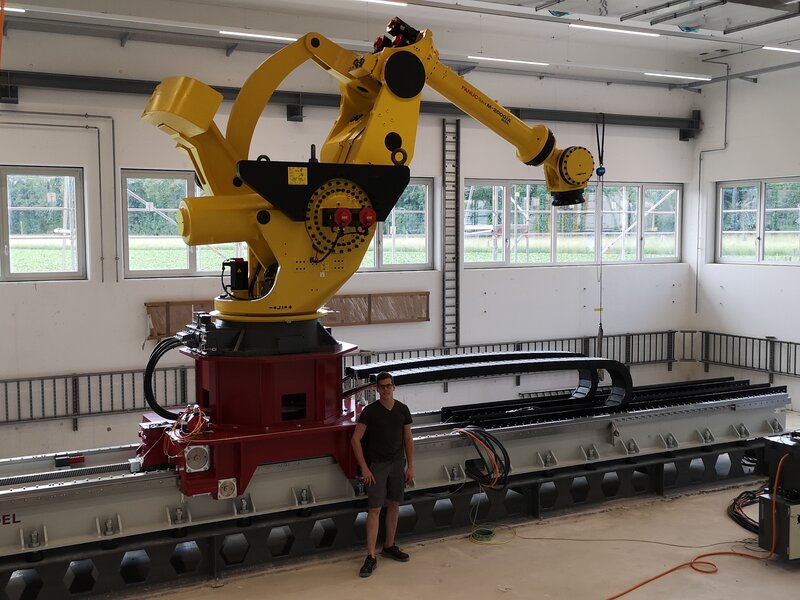

The largest robot in Switzerland

Swiss precision at Gewinde Ziegler AG since 1932

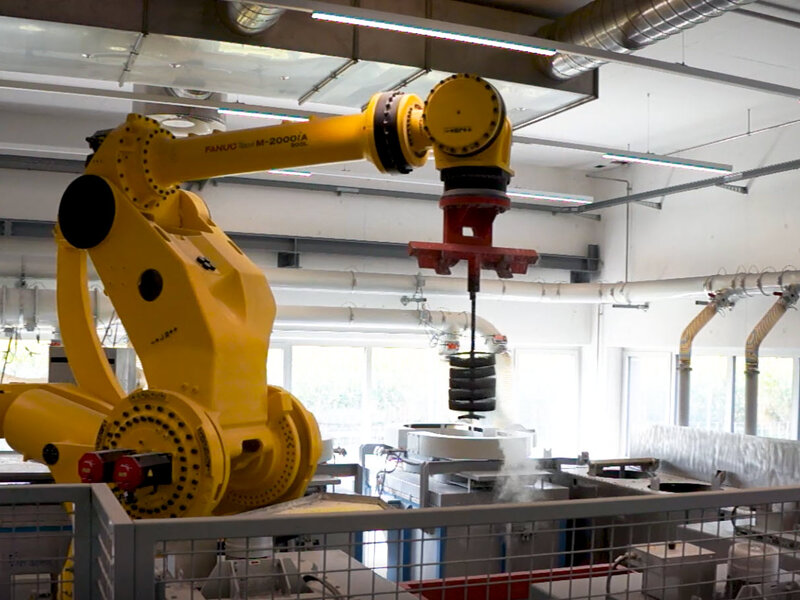

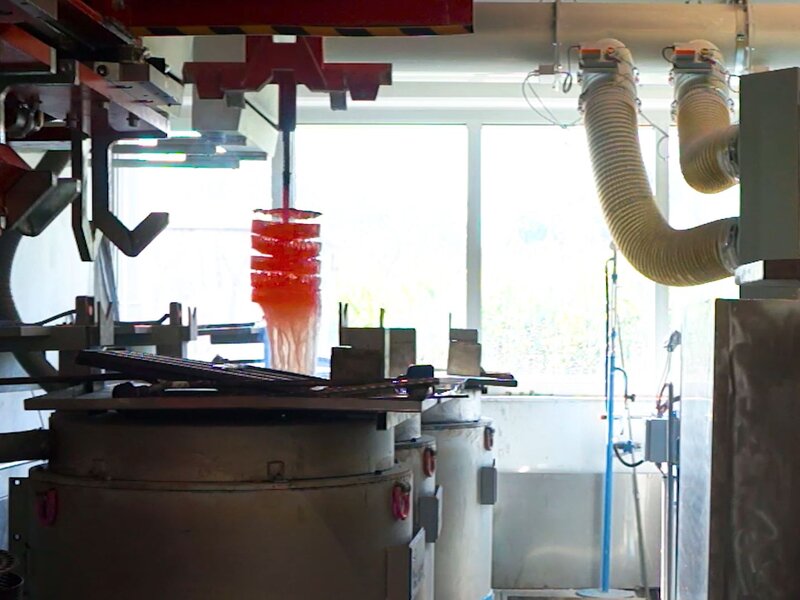

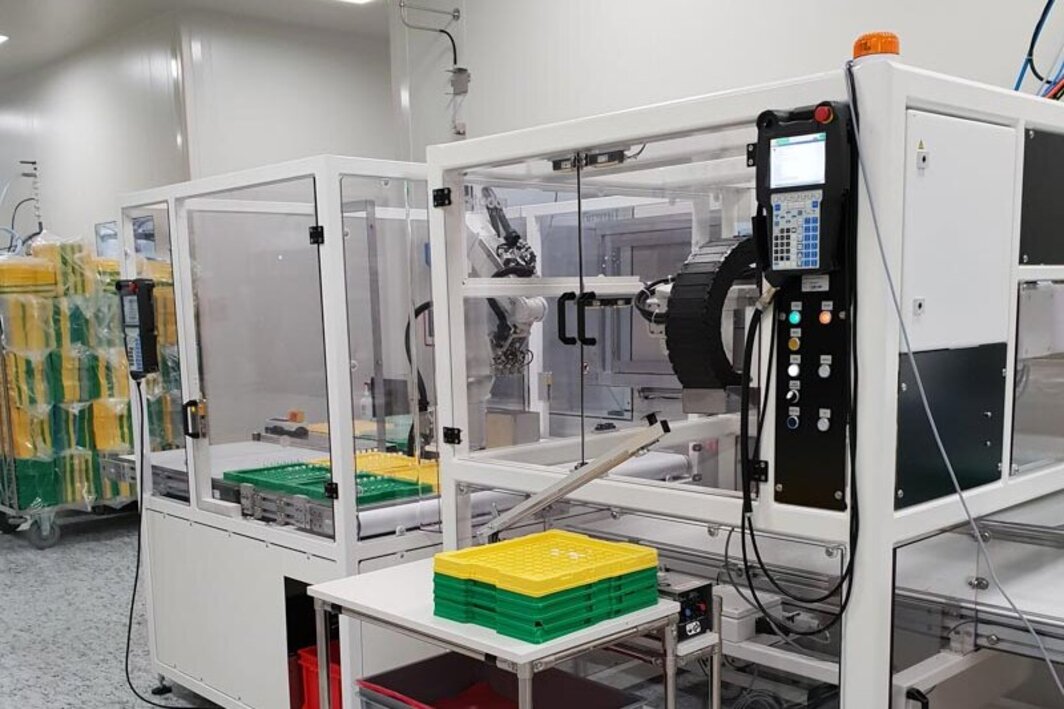

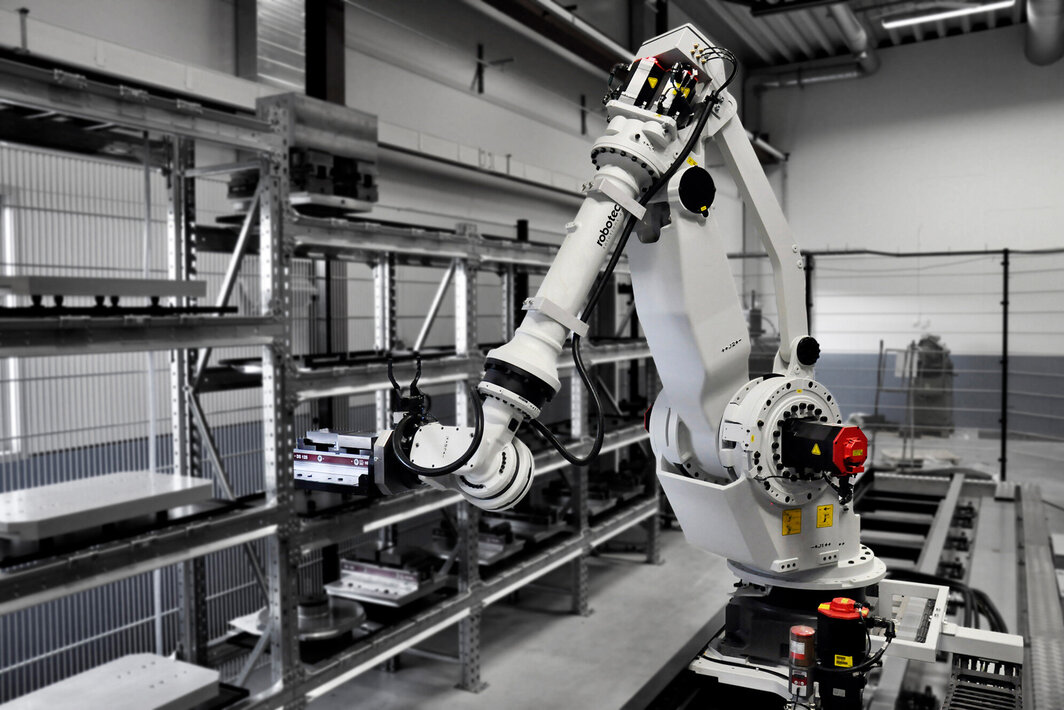

Gewinde Ziegler AG has, with its new hardening shop in 2019, fully automated the process of salt bath hardening. By introducing new processes, such as induction hardening and core hardening, our long-standing customer is now able to thermally treat steel shafts up to 10 m of length. With the use of an industrial robot on a linear axis, processes can be carried out in a well controlled and safe manner.

-

Challenge

With a lot of courage and knowledge, Gewinde Ziegler has taken on the task of fully automating the processes that are not common. A powerful robot on a linear axis is to handle the hanging steel shaft products between various baths and furnaces - and this in a specially built building.

-

Solution

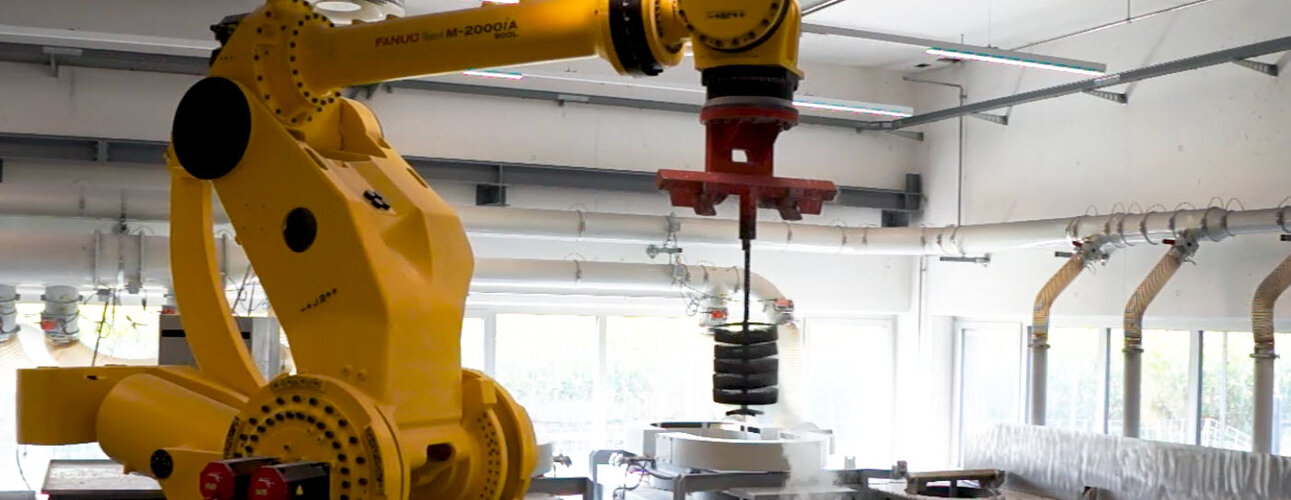

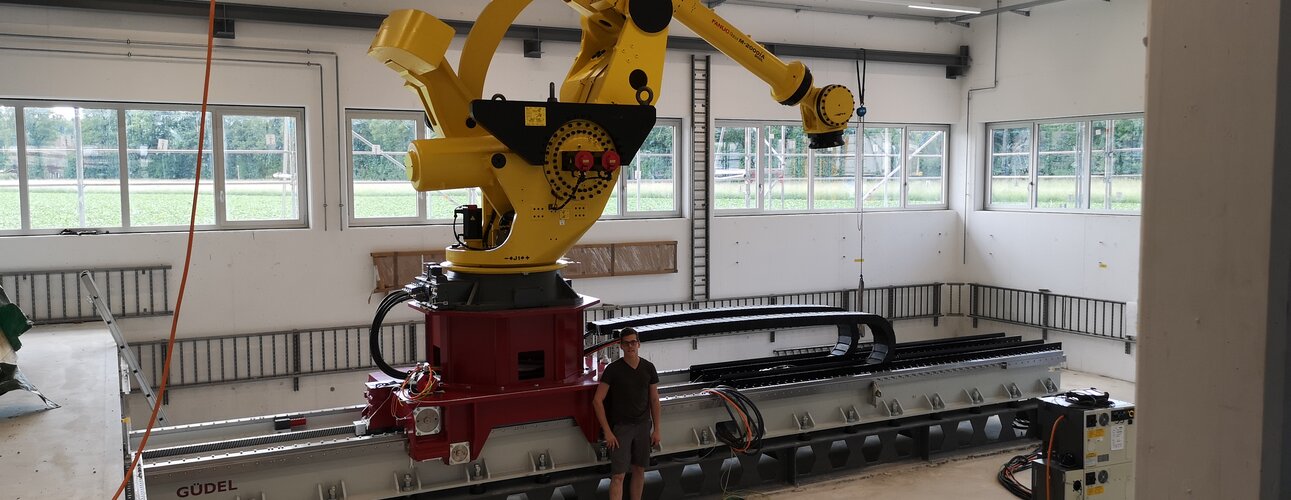

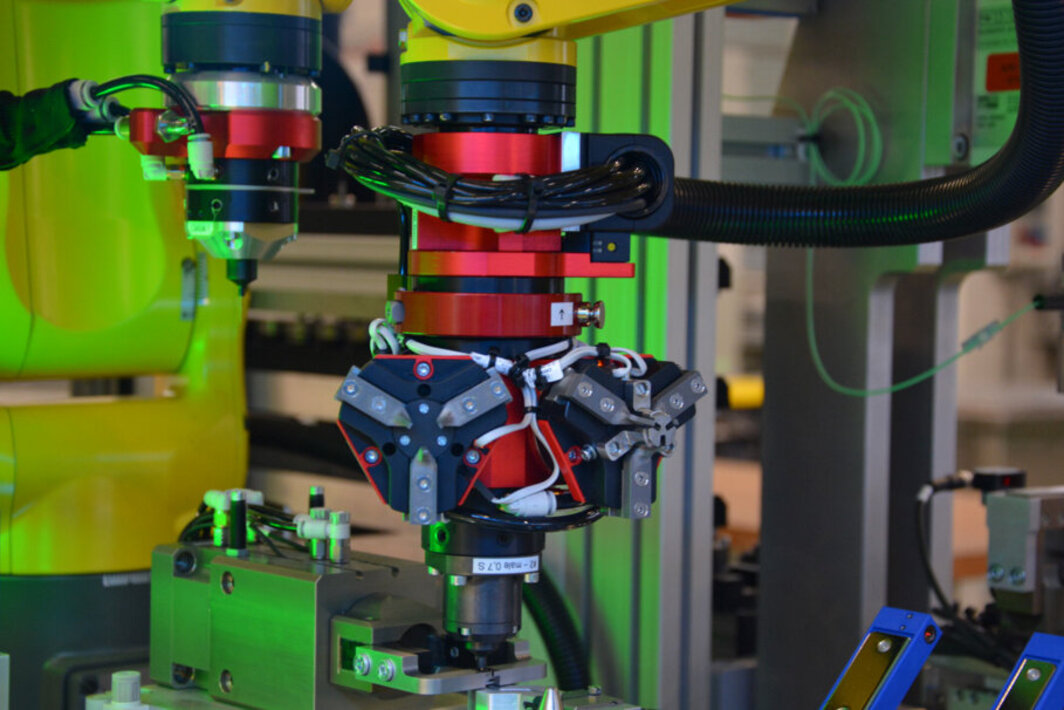

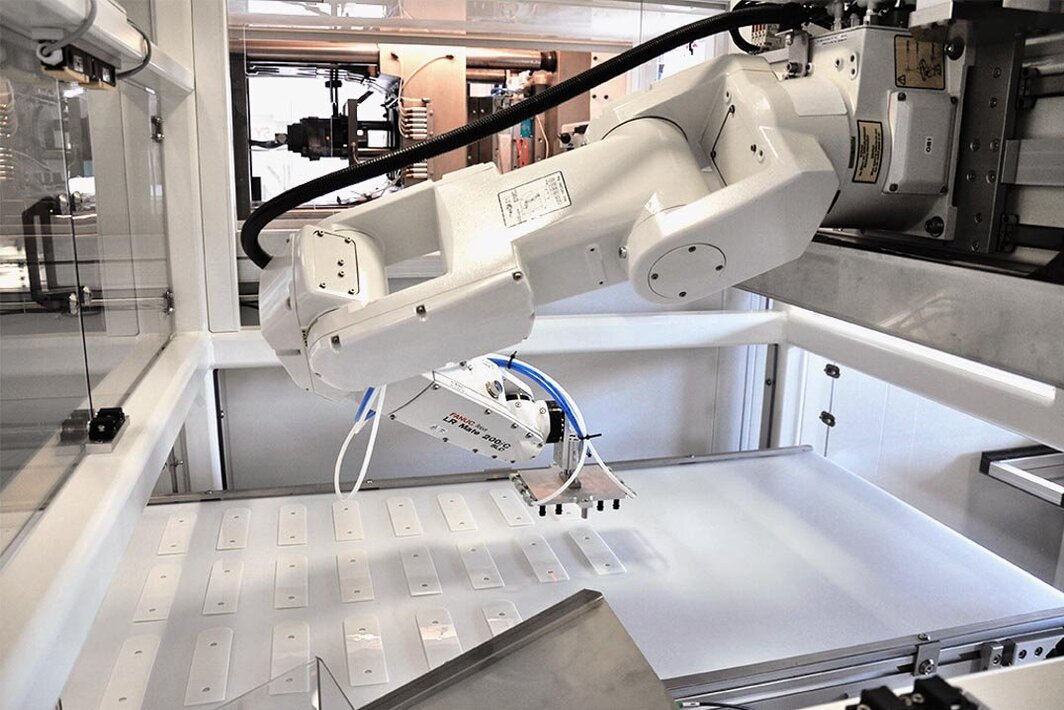

The Fanuc large robot with flexible gripper system moves very smooth from A to B. With a payload of 900 kg and a reach of 4.5 m, the installed industrial robot is the largest in Switzerland. And it stands on an 8-meter-long traversing axis on a 1-meter-high riser, which gives it a huge working range - both vertically and horizontally. A control system developed by the customer directs the many process steps.

-

Conclusion

With these high dimensions, it was essential to include the building in the automation planning. During installation, the large robot set up had to be brought into the building first, followed by all the peripherals. Courage, skill and timing were required for all parties. Today, the system runs 24/7 and allows Gewinde Ziegler to manufacture all processes for their products in-house. It is incredibly impressive to see this tame monster in action. Robotics small & fine - or big & strong. We do it!

-

Special features

- Robust Fanuc robot M-2000iA

- on Güdel axis with 8m travel

- Autonomous and safe processes

Nick Koch, CEO / Verkauf