CASE

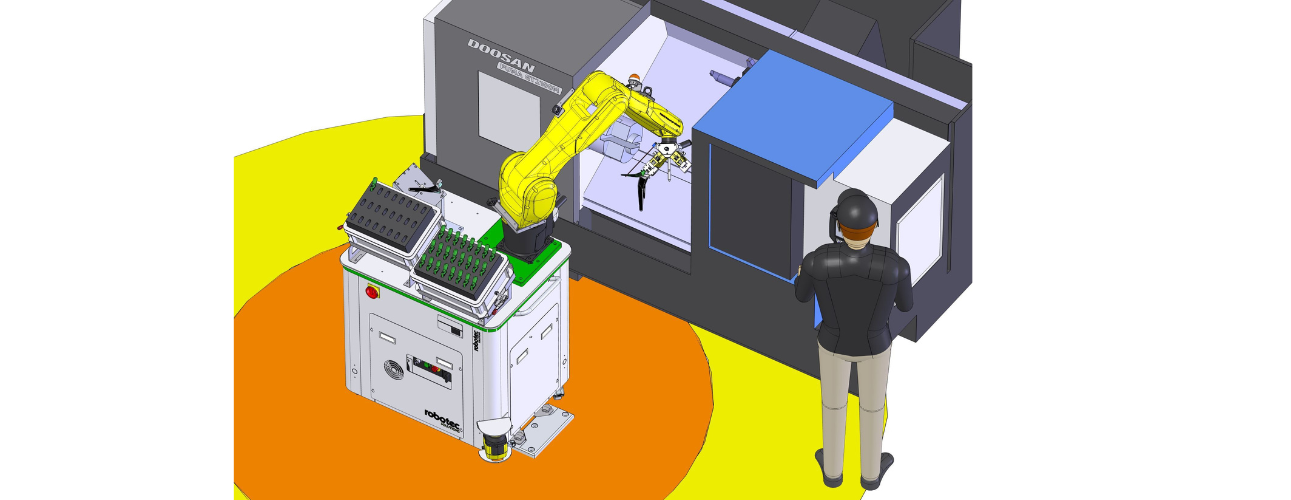

Mobile robotic cell R-Cobot in MedTech production

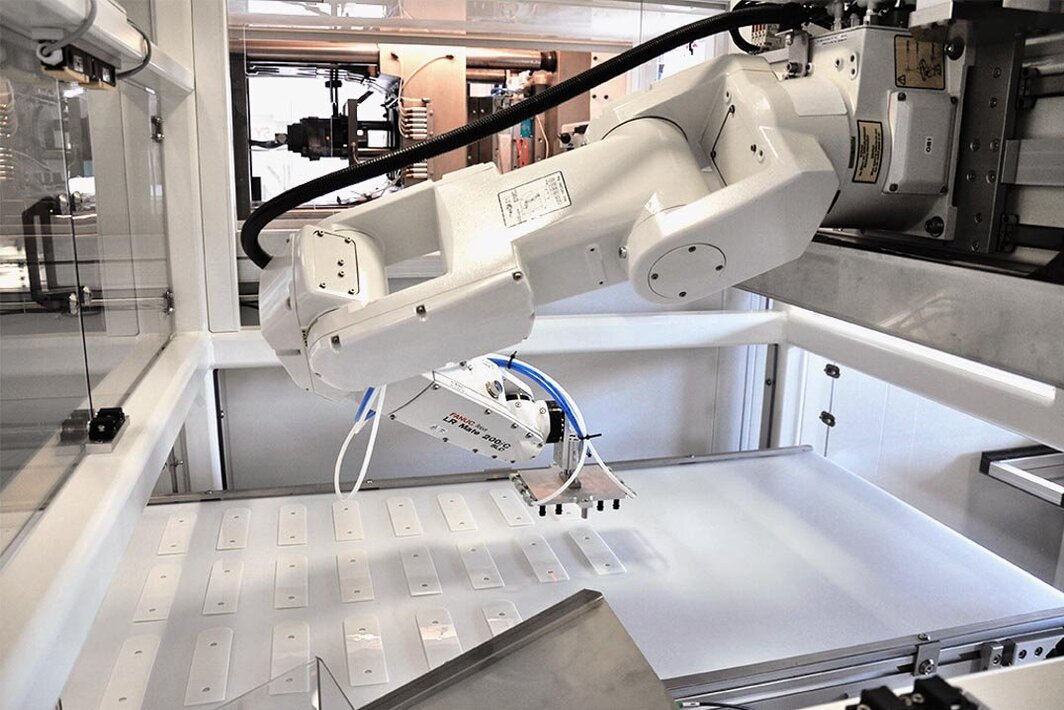

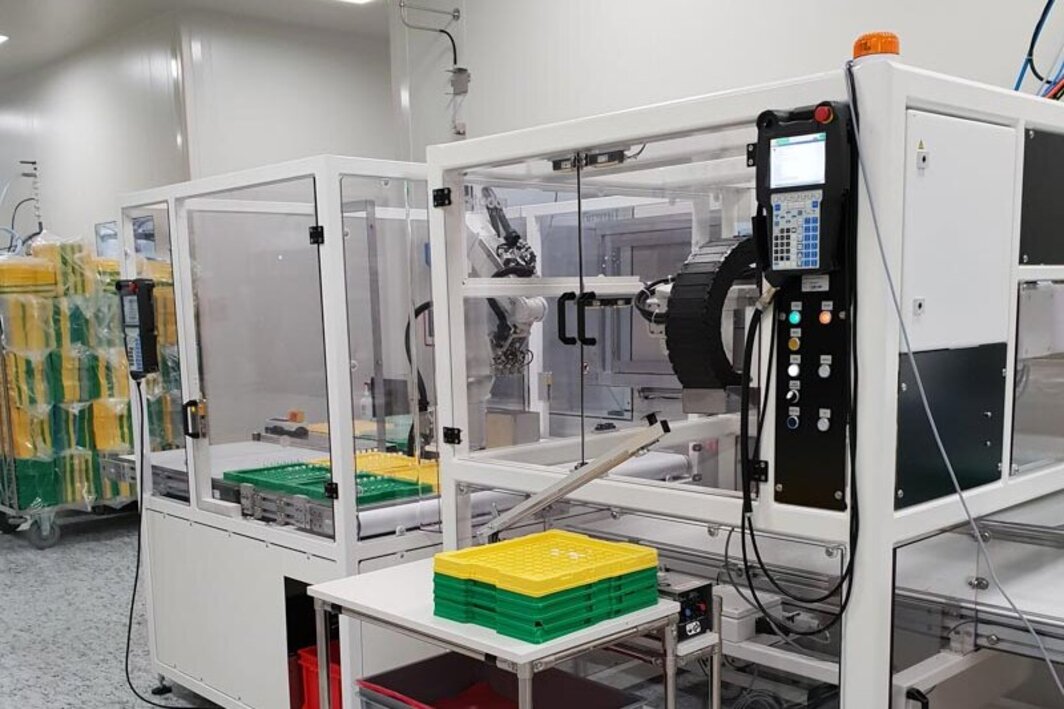

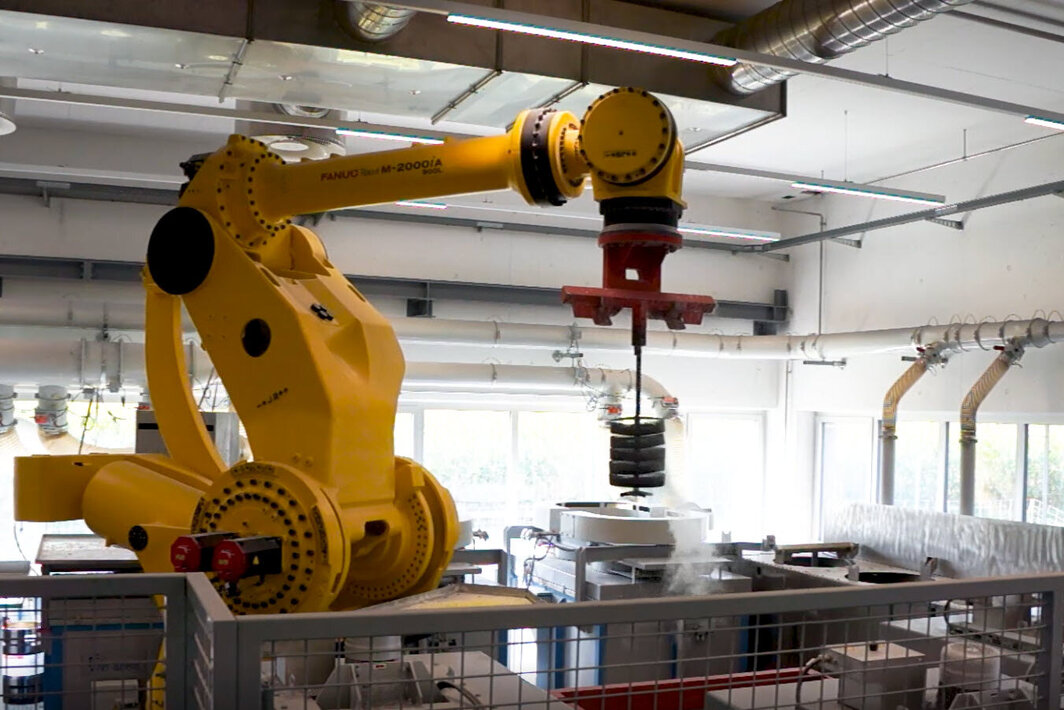

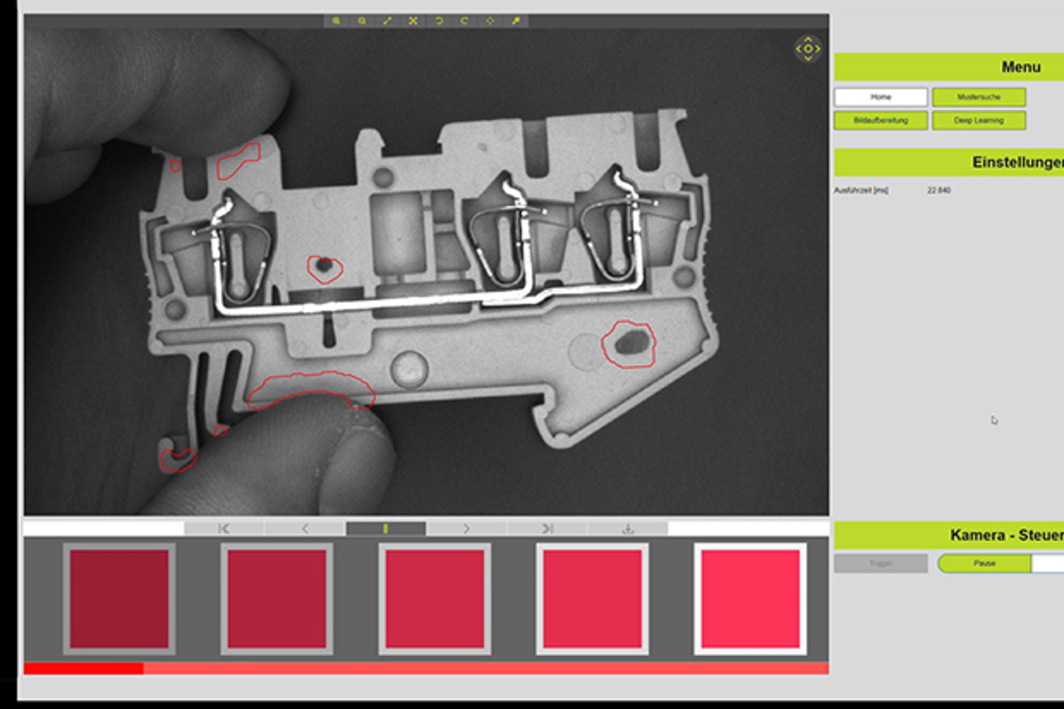

Precise parts are manufactured at a MedTech supplier in 24/7 operation. Highly automated turning/milling combination machines are used for this purpose. Barrier-free accessibility was a must criterion. A modular basic cell R-Cobot with standard Fanuc industrial robots and two safety scanners automates loading and unloading. Cleverness of the robot cell with tactile gripper, blow-off and press-on function, gripping station and other functions make the production cell very easy to operate. And the "Easy-to-Use" operator interface allows the customer to easily teach-in and teach-in new reference parts.

-

Task

Medical parts are produced in a very limited space by means of milling/turning machines in 24/7 mode. A fast and precise milling machine processes the raw parts down to the micrometer. Unmanned loading should be ensured by a mobile robot cell. The tricky part is the tight space conditions, the high variety of references, and the desire for a "cell without a protective fence" for good accessibility.

-

Solution

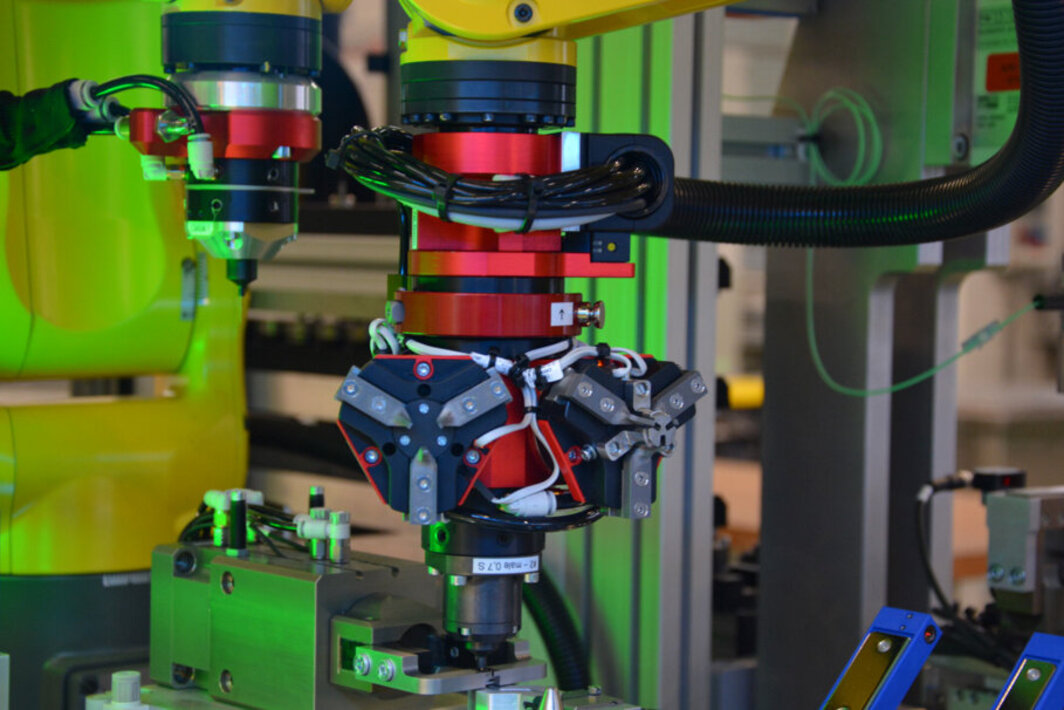

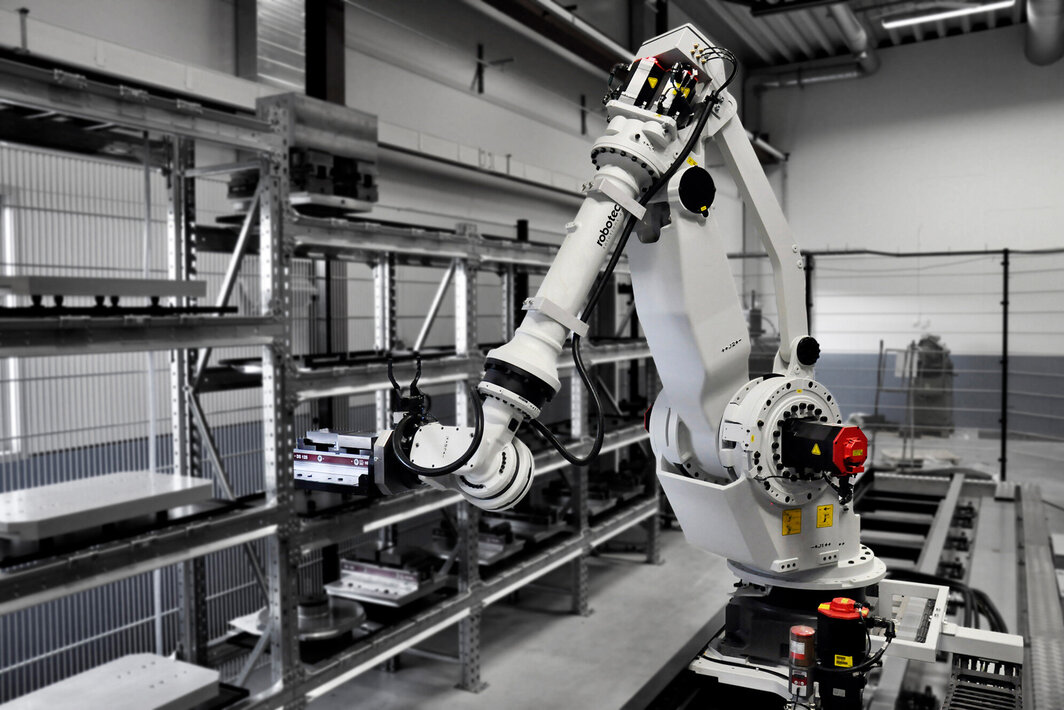

A standard Fanuc LR-10iA industrial robot of the latest generation with DualCheckSafety option and two safety scanners was placed on the modular basic R-Cobot cell. This allows barrier-free loading and unloading of the cell. A self-start feature, after filling the parts storage and leaving the safety zone, has been set up to further increase the comfort level. The travel speed of the robot is equipped with multifunction gripper and blow-off tool. When you are near the machine it is limited and safe, but when you are out of the safe zone a fast changeover/blow-off cycle can be run. Safety monitoring is provided by two vial scanners with safety PLC. The cell, which is mounted on wheels and fixed by an accurate quick-clamping system, can be removed for cleaning purposes and easily brought back into place. An "Easy-to-Use" operator interface allows the customer to easily teach-in and teach-out new reference parts.

-

Conclusion

Modular cells with robots and multi-function grippers allow high functionality and efficiency in a small package. The areas monitored by area scanners establish a new standard of comfort for an automation cell and make an industrial robot a better cobot with all its speed and durability.

-

Special features

- Modular cell concept

- Safety area

- Precise and fast where needed

- Industrial and robust

- Cell is comfortable to load

- Easy-to-use operation

Nick Koch, CEO / Verkauf