CASE

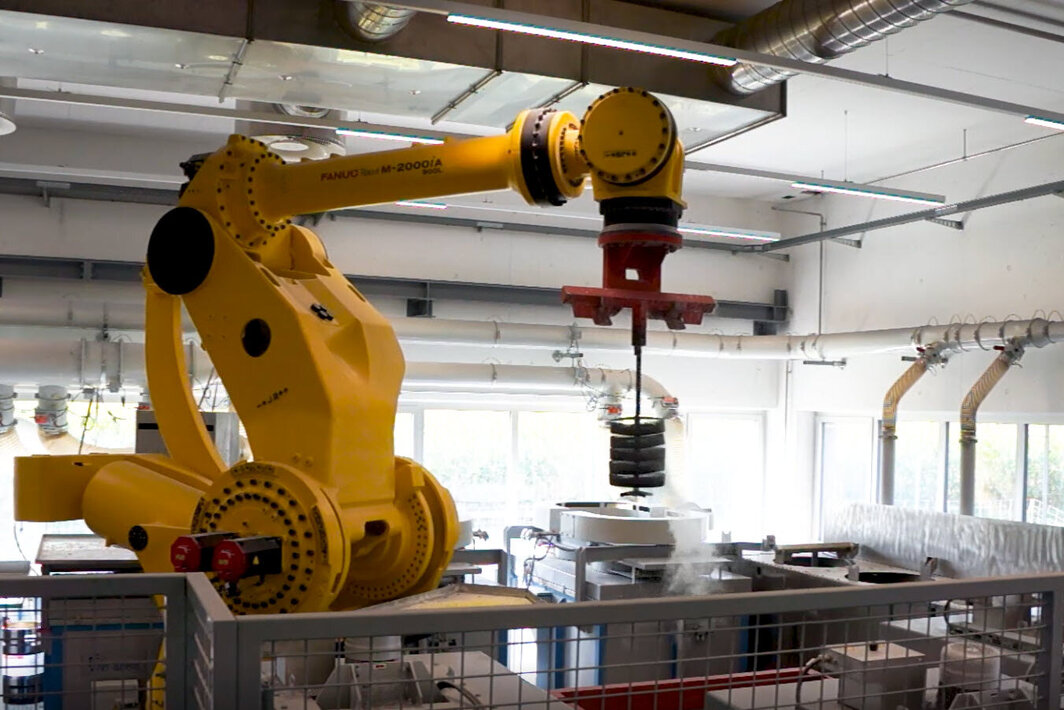

Automated handling in the clean room

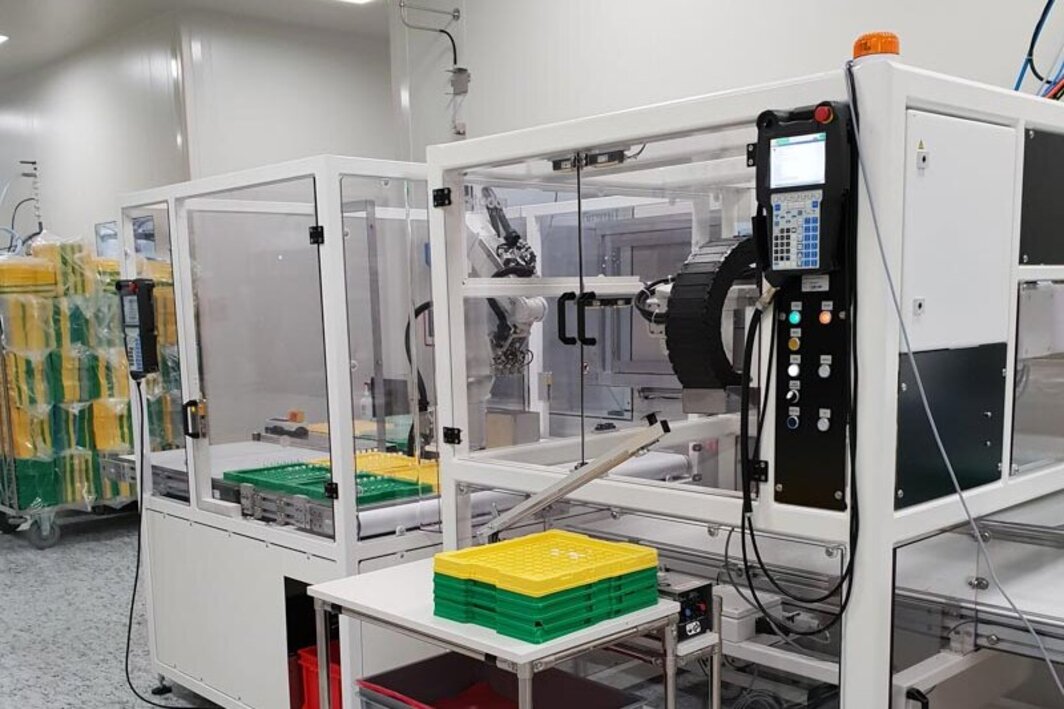

In the clean room, delicate parts are fed from blisters to an automatic assembly machine.Tight space conditions and a fast cycle time lead us to use 6 robots distributed over 2 cells. With various stations, such as destacking, turning and spreading stations, camera checks, we enable the robots to work hand-in-hand and to meet all the requirements set by the customer regarding autonomy, cycle time and quality.

-

Challenge

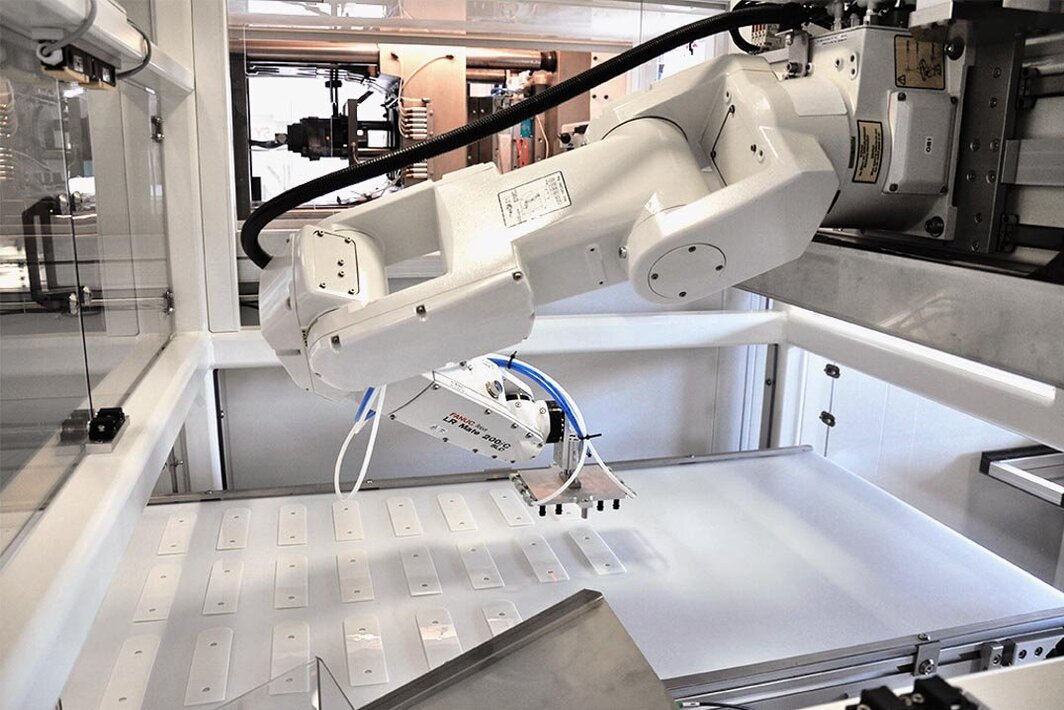

Under clean room conditions, the raw customer parts are inserted from blisters into a circulation system. In this existing system, the sensitive customer parts are further processed and finally returned to our automation system. Once there, the finished customer parts are packed back into the blisters and stapled. The high volumes and fast cycle times require an efficient and safe concept.

-

Solution

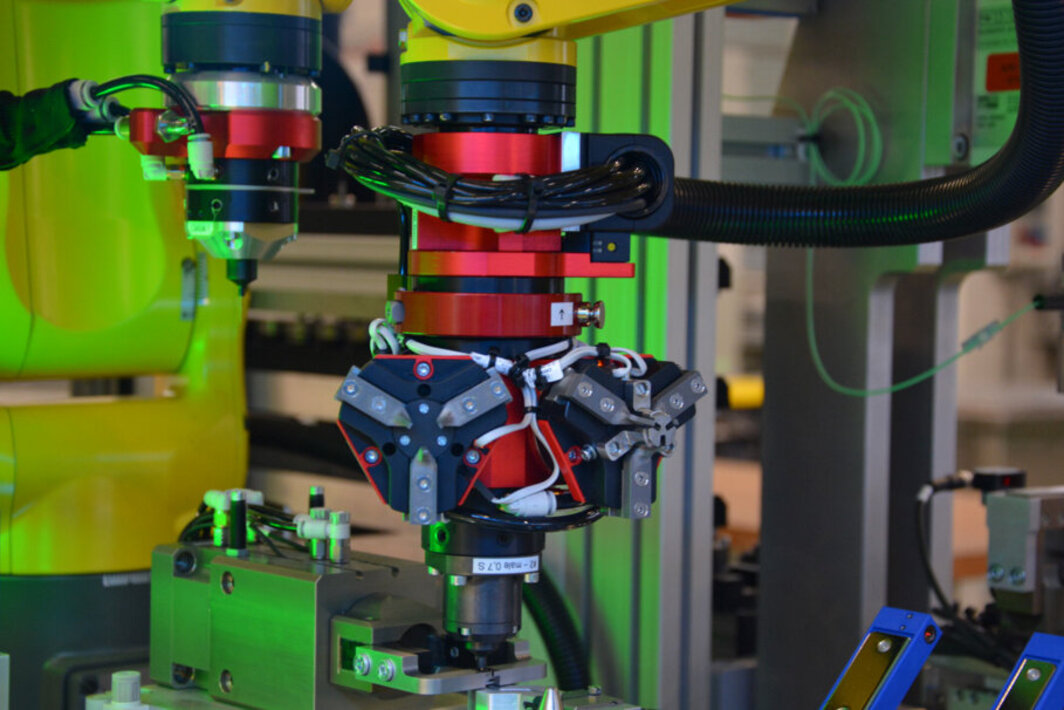

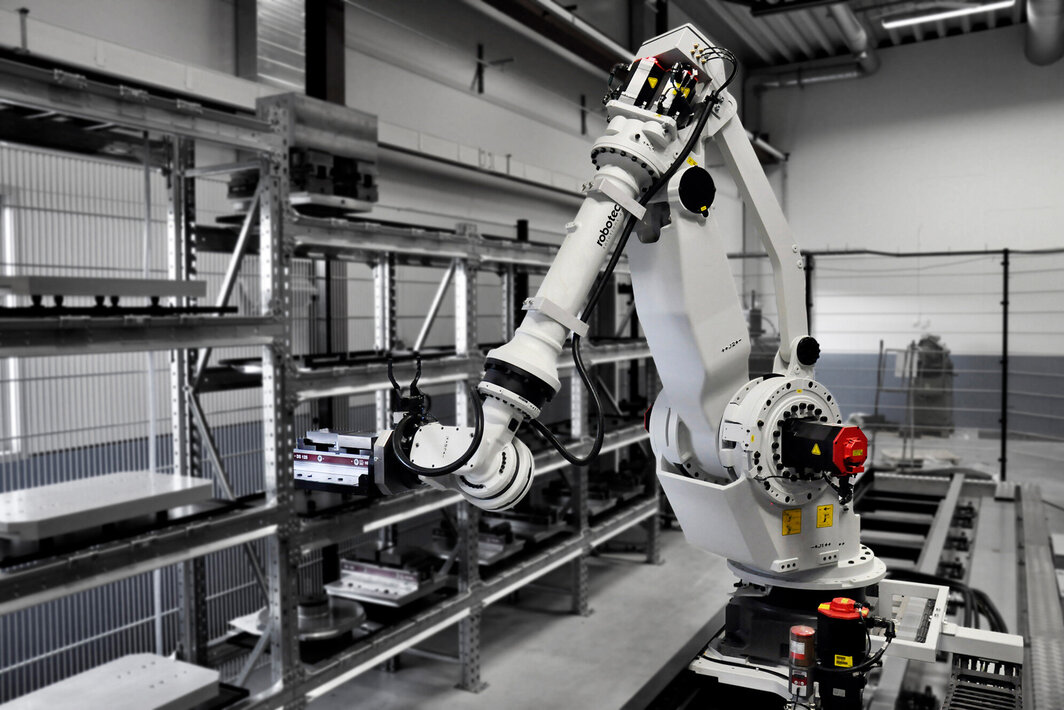

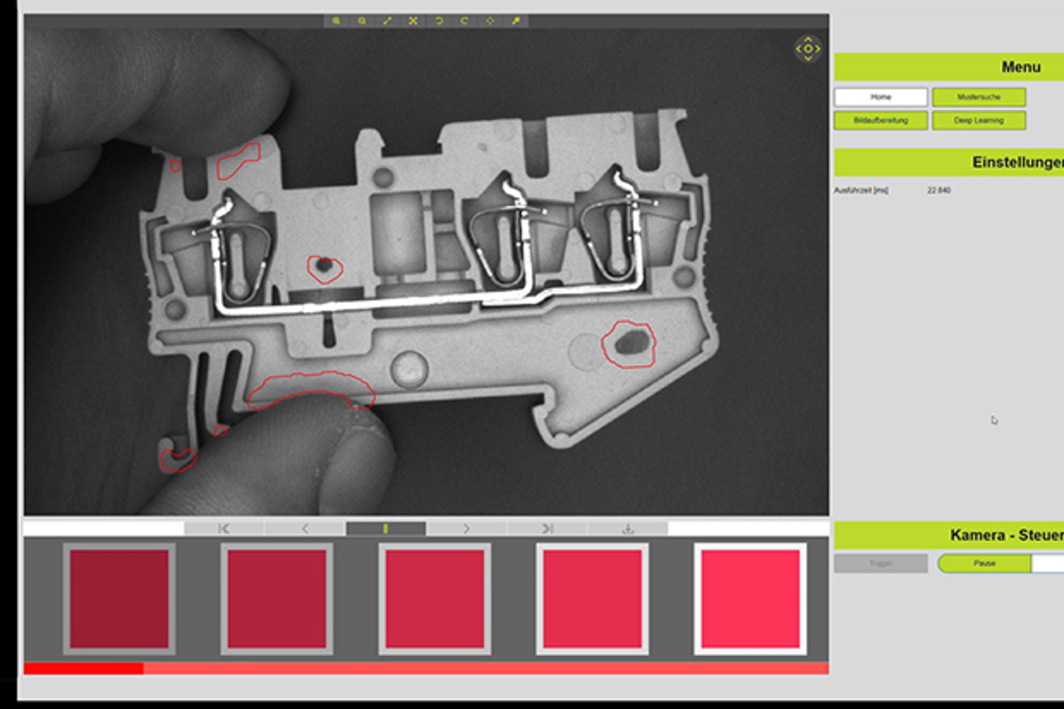

In order to achieve the required high level of autonomy, it had to be possible to feed several stacks of blisters at once. These are automatically stacked in the machine and checked by a camera system. The customer parts are moved by 6 robots. Due to the high quantities, several parts have to be handled at the same time. This is achieved by using a multi-gripper and various gripping stations. The complete system is located in a clean room and is according to that mechanically designed. The machine is controlled by a clear HMI, on which all processes are comprehensible, as required in the pharmaceutical industry.

-

Conclusion

To meet the high requirements, Robotec Solutions relies on selected quality products. The solution finding is based on many years of experience and is developed together with the customer. Robots, grippers and software always form the heart of such a system. All system components are developed and built by us - so we can offer our customers a clean and harmonious solution. The in-house know-how simplifies validation and guarantees up to 20 years of support and spare parts availability.

-

Special features

- Interaction of several robots in a very limited installation space.

- Parts in direct contact with the product made of clean 3D printed parts so that they are always precisely guided.

- Clean room design

- CE approval

- Traceability on clear HMI

- Over 100 sensors per cell guarantee trouble-free operation and consistently high quality.

- Validation according to GAMP

- Compact size in limited clean room space

- Short interruption of production at the customer's site due to efficiently planned installation, connection of the existing system with our robot automation and commissioning of the entire system.

- Thanks to the good cooperation of all departments, the tight time frame could be kept despite delivery bottlenecks of some sub-suppliers.

Nick Koch, CEO / Verkauf