CASE

Tobacco bale handling with gentle giant

The tobacco industry is still one of the largest economic sectors in Indonesia. In order to meet the demand for cigarette production, stable and reliable automation systems are required. Thanks to our branch office in China, we were able to place an appropriate robot solution in close cooperation and put one of the largest industrial robots on the market into operation in Indonesia.

-

Challenge

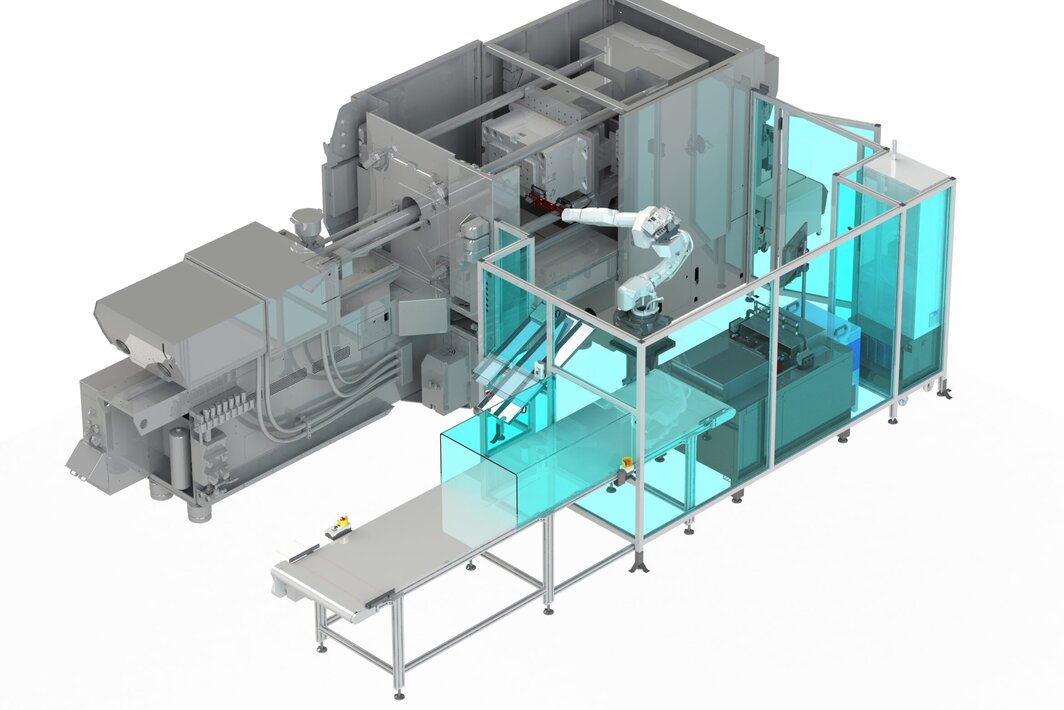

The tobacco bale cartons delivered by local farmers are for the most part completely crumpled and dented. This makes the design of a process-safe automation extremely challenging. In general, the handling of the bale cartons on site with the forklift is very rough and rustic. The goal was therefore to integrate a robust robotic cell into the existing cigarette production line that could handle the bulky cartons and be easily and intuitively operated by the personnel there.

-

Solution

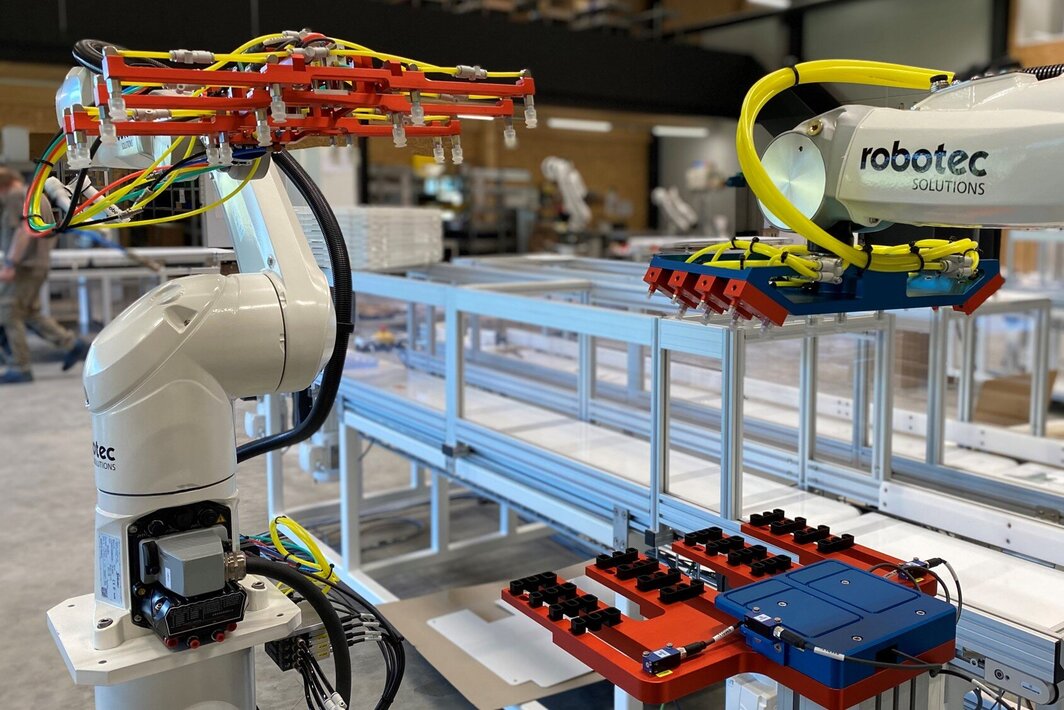

A Fanuc giant with a payload of 700kg and a gripper as big as a closet effortlessly picks up the damaged cartons from the infeed conveyor and gently presents them to an operator. The most process-safe way to open the cartons is still in the hands of a human operator. Thanks to the built-in safety features in the robot controller, the operator can safely open the carton while it is still being held by the robot. A simple push of a button on the robot's gripper signals the system that the carton has been opened and the robot continues its process, depositing the bale of hay on the conveyor belt.

-

Conclusion

Collaboration between robots and humans does not only exist in laboratory environments. With seriously evaluated and correctly implemented safety precautions, large industrial robots can also work together with humans. In this way, the power of a robot and the dexterity of a human can be combined to create a perfect process flow.

-

Special features

- Collaboration between one of the largest industrial robots and humans

- Double safety thanks to Fanuc Dual Check Safety

- Integration of the robot cell into a running production without its interruption

- Process reliability despite harsh conditions

- Design & test setup at Robotec - final assembly and commissioning in Indonesia

Nick Koch, CEO / Verkauf