CASE

Efficient palletizing for Bruno’s Best

Bruno’s Best makes fresh, well-balanced salad dressings with seasonal ingredients that appeal to a wide range of connoisseurs and food lovers. The company is a singular success story, and the creativity of the company’s founders – the Arnold family – is truly impressive.

-

Task

In order to deliver just in time and meet steadily growing consumer demand, palletizing systems with upstream packers/shrink-wrappers were required.

-

Solution

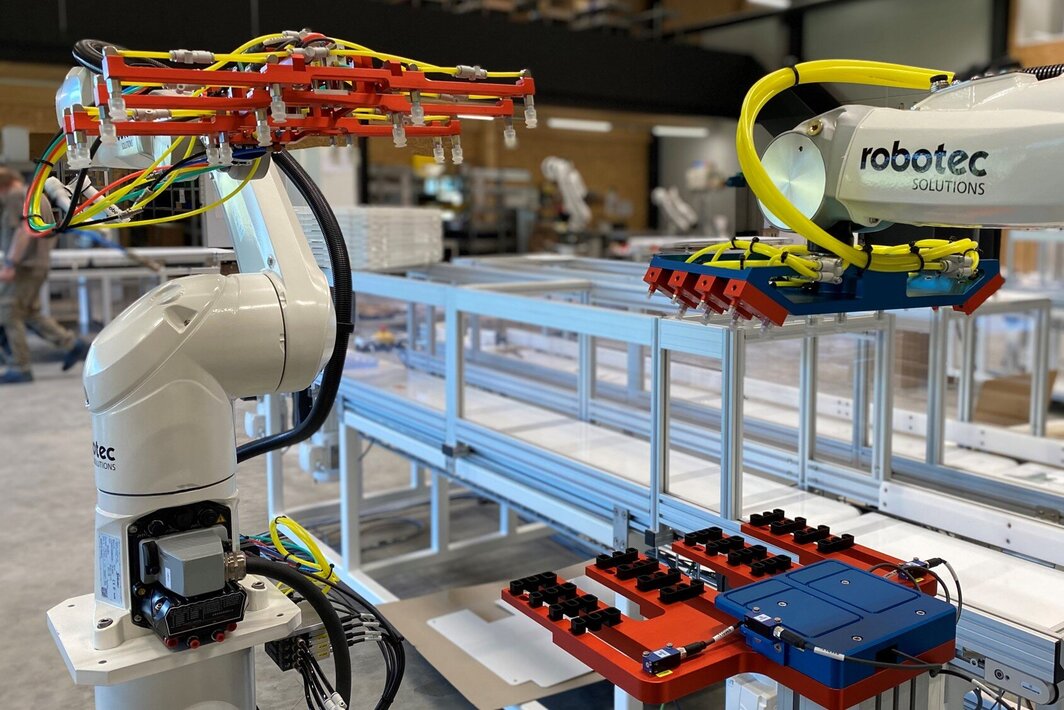

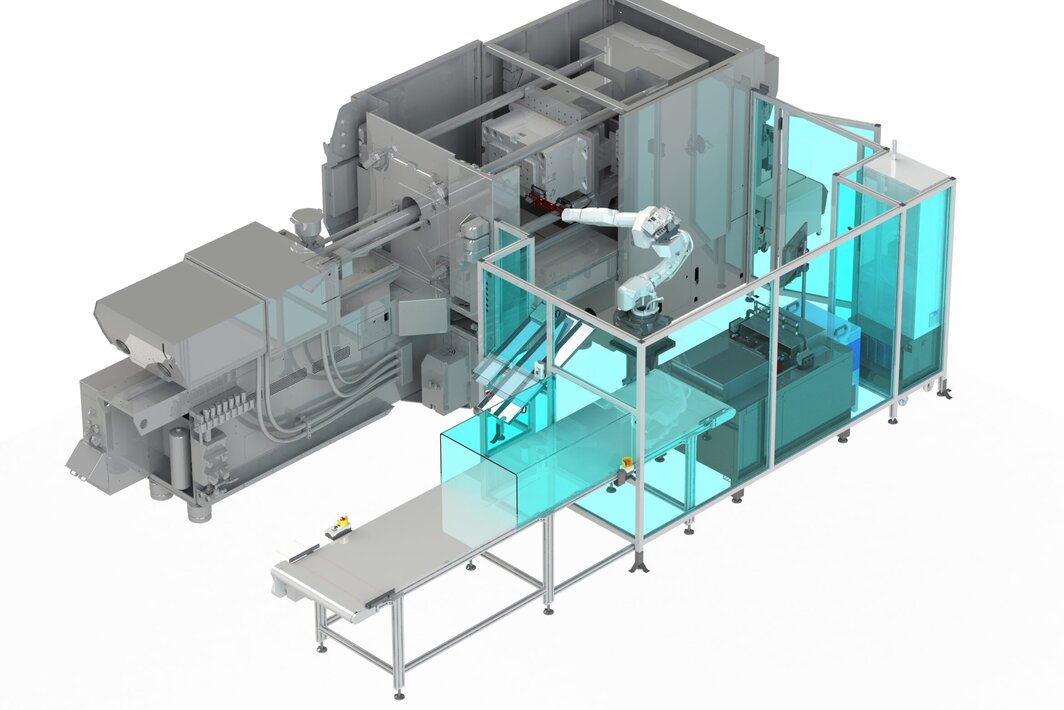

An industrial robot with a high payload carries out the palletizing tasks at the desired cycle rate. Empty EUR-pallets are stacked in a hopper and, if necessary, transported by the robot via the roller conveyor. The robot picks up an intermediate layer of cardboard and starts stacking the packages. The bottle packages are initially grouped, positioned, and packaged/shrink-wrapped to create units. Depending on the layer arrangement, the robot can pick up between one and four packages and create a stable stack with them. Once the entire palletizing schema is complete, the pallet is transported autonomously from the cell and shrink-wrapped with protective film.

-

Conclusion

The conceptual design and the construction of the feeder/gripping technology required us to call on all of our skills. A large number of preliminary tests and subsequent in-house developments resulted in a compact, powerful production machine. Due to the lack of available space, a clever gripping system was required in order to optimally take advantage of the robot’s degrees of freedom.

-

Special features

- Multi-functional gripper

- Central control via HMI

- Simple tool-free conversion

- Easy to expand with new palletizing schemas

- Food-safe environment

Jörg Lanz, Sales