CASE

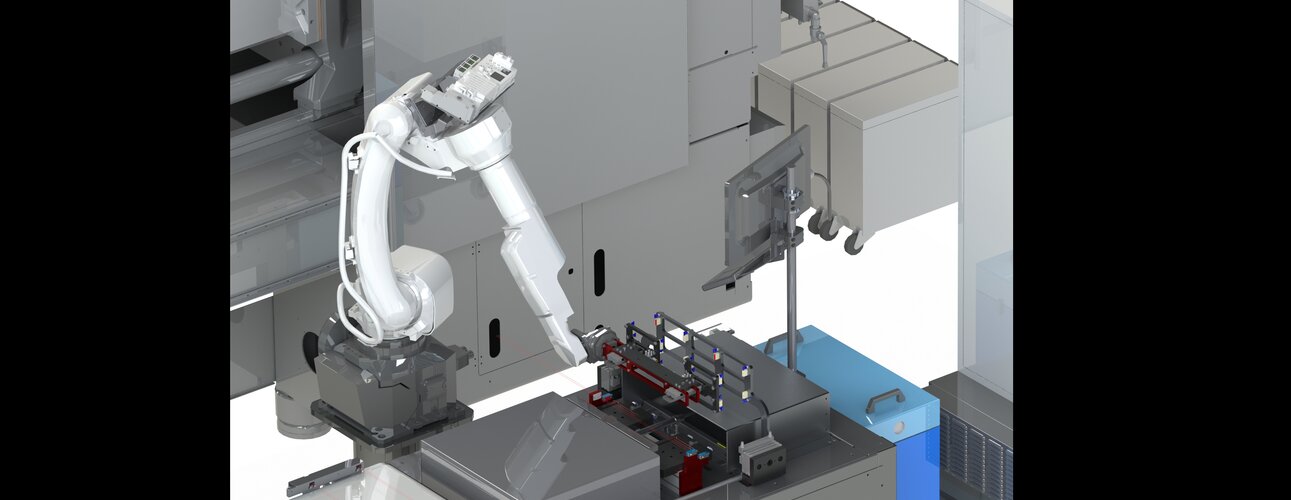

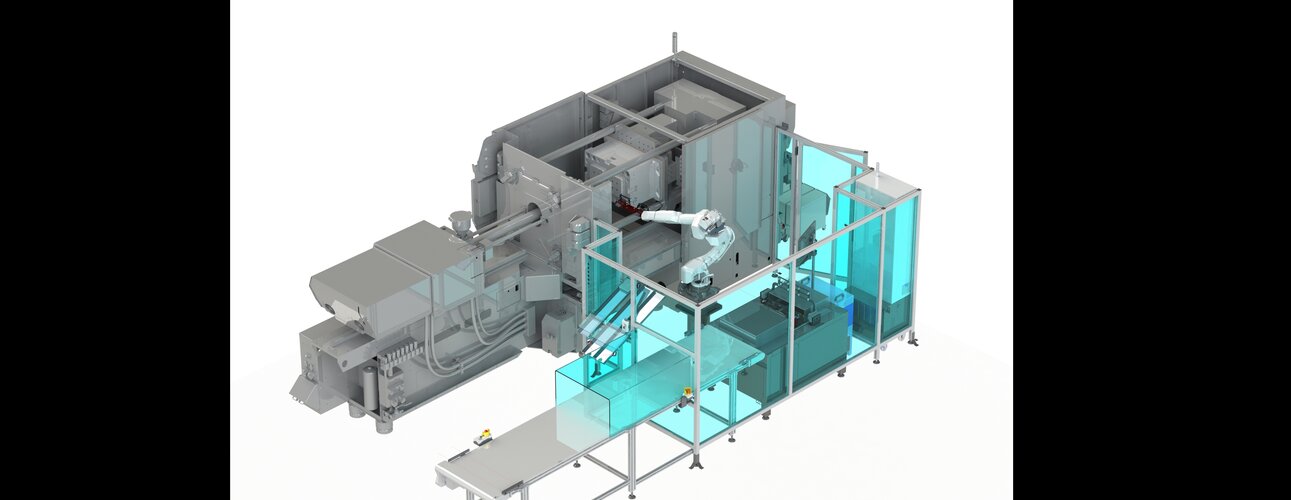

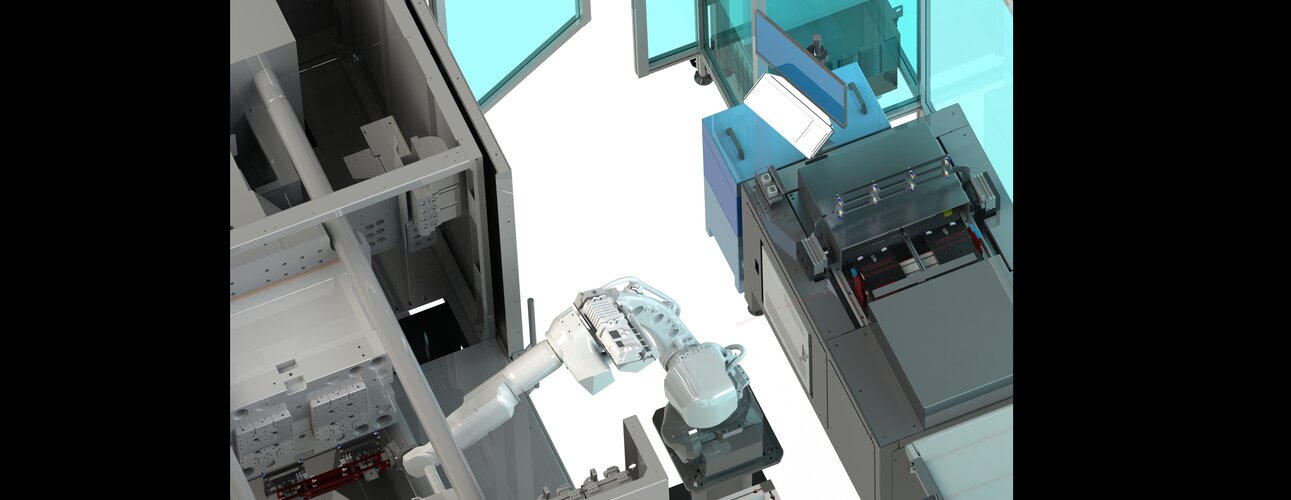

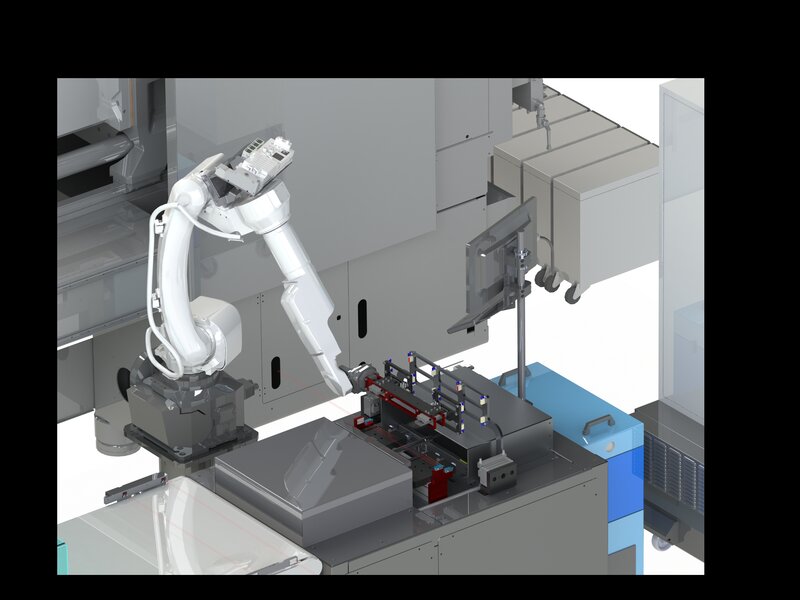

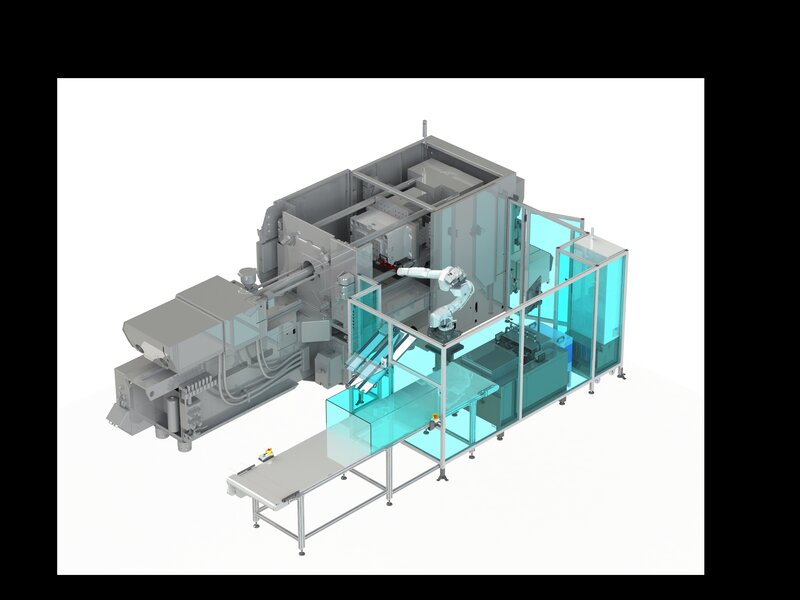

Injection molding machine extraction

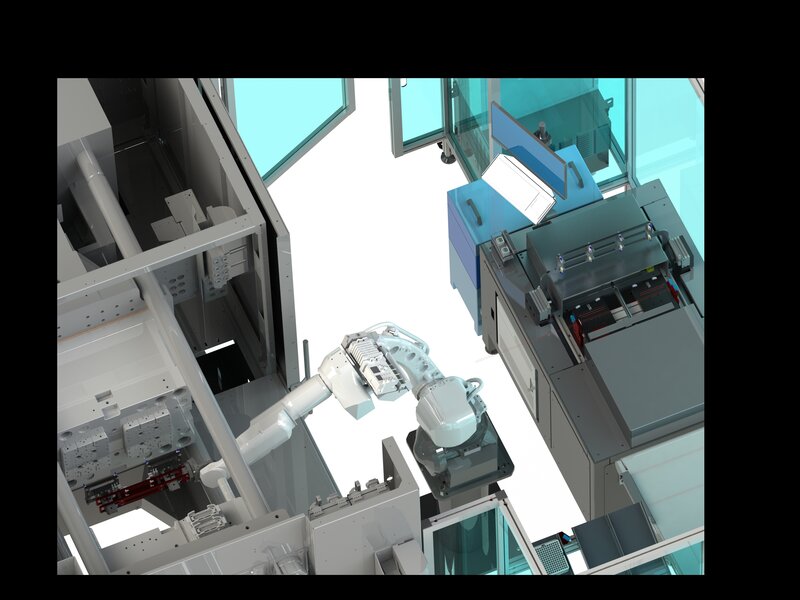

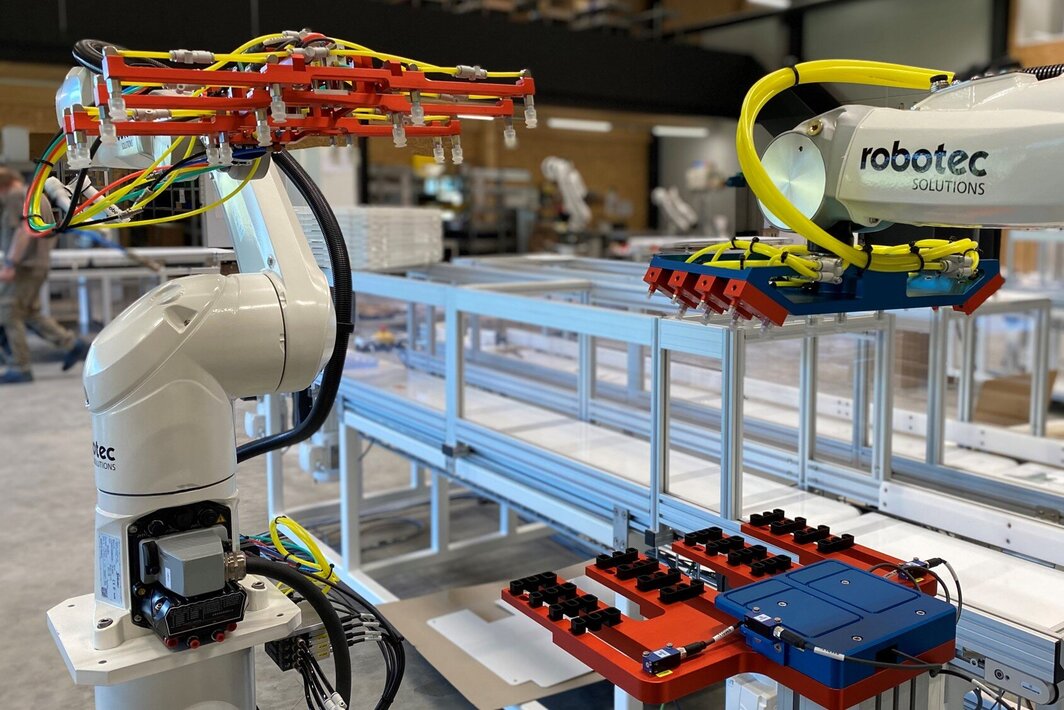

A Fanuc 6-axis robot on a stable steel base removes two plastics parts from the injection molding machine using a part-specific gripper. The removed parts get labeled with a customer-specific laser before being stacked on the conveyor belt. Rejects and start-up parts from the injection molding machine are discharged on a chute provided for this purpose. Q-parts can be requested via a button and discharged on a separate chute.

-

Task

The challenge was to meet the required cycle time and to generate a stable laser process that it meets the (end) customer requirements. Likewise, the system must meet the given cleanroom requirements.

-

Solution

After an evaluation phase of a suitable laser for the marking of the plastic parts and the determination of the laser supplier, the necessary preliminary tests could be realized. After several laser tests in close cooperation between engineering, laser manufacturer and customer, a well-functioning laser station has been developed and built. Thanks to our many years of know-how, a compact and well engineering robot cell has been installed to the customers satisfaction. The system also meets the clean room requirements and is documented and certified according to GMP.

-

Conclusion

A good and precise preliminary work with all necessary clarifications is an optimal start to realize such a project successfully. Also, through our internal logged inspection and test phases, we successfully passed the FAT (Factory Acceptance Test) and SAT (Site Acceptance Test) and were thus able to hand over a flawlessly functioning robot cell to the customer without any delays.

-

Special features

- Simple and safe operation over a HMI

- Clean room design

- Integration of marking laser

- Fast cycle time

- high level of functionality on limited space

Jörg Lanz, Sales